Case Study SPC 1500 - 4000

HGG Case Study at Alltype Engineering

WATCH VIDEO

About this case

introduction

Perth, Australia is one of the world’s most isolated cities. Being located in that isolated area, Alltype Engineering took the opportunity to offer their clients a comprehensive range of multifaceted, multidiscipline and complex fabrication and welding projects.

Being that versatile, Alltype Engineering knew they had to invest in automation in order to increase their production efficiency. Wasting time of their skilled craftsman was a major bottleneck for Alltype Engineering. Chief Operating Officer, Colin Heitman, knew that the HGG machine would be the largest labour-saving machine that I could put into my business’.

14

Month payback period

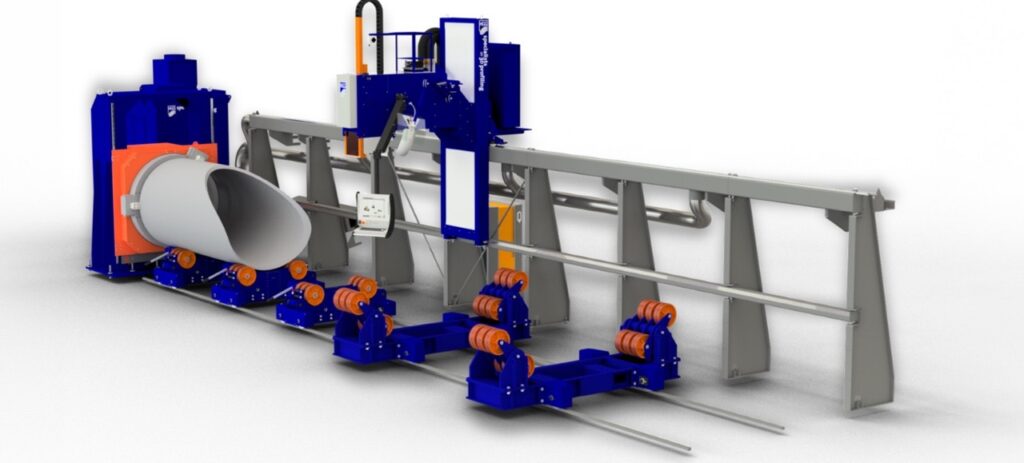

SPC 1500 - 4000 PT

2035 mm

Max pipe width

SPC 1500 - 4000 PT

30%

Saved on labor costs

Alltype Engineering

1985

Established in

Alltype Engineering

1.1 year payback period

Alltype bought an HGG SPC Cutting Machine, a decision that Heitman still doesn’t regret. Highly skilled welders used to waste a lot of time on grinding. ‘I recognized that the SPC Pipe Cutting Machine would save us a lot of grinding, a lot of expensive work. Welders are hard to find. That’s exactly why I bought this pipe cutting machine.’ The machine’s payback period was 1.1 year. Any machine that does that, is worth the investment,’ Heitman concludes.

Fabrication glory

Operators love working with the SPC Pipe Cutting Machine, chasing automation with high accuracy and versatility: profiling pipes from 100 mm up to 2035 mm (4–80”) thickness are no problem at all.

The SPC Pipe Cutting Machine is one of the best – if not the best – machines to work with. One of the operators, Mark, calls it a really efficient machine with very little waste of material. ‘One of the greatest advantages we found is that it’s very easy to go back and change or alter something, if you need to.’ ‘It’s a really easy machine to operate. Just follow the instructions that are coming up on the screen.’

By automating the cutting process and applying smart weld preparations like bevels, materials are ready for fast and easy fit-up and welding. The accurate bevel cuts significantly reduce weld volume and time. As a result, Alltype Engineering managed to reduce on-site labour costs by 30%.

The machine helped to optimize their cutting process and allowed welders to do what they do best: welding.