Product Tour RoboRail

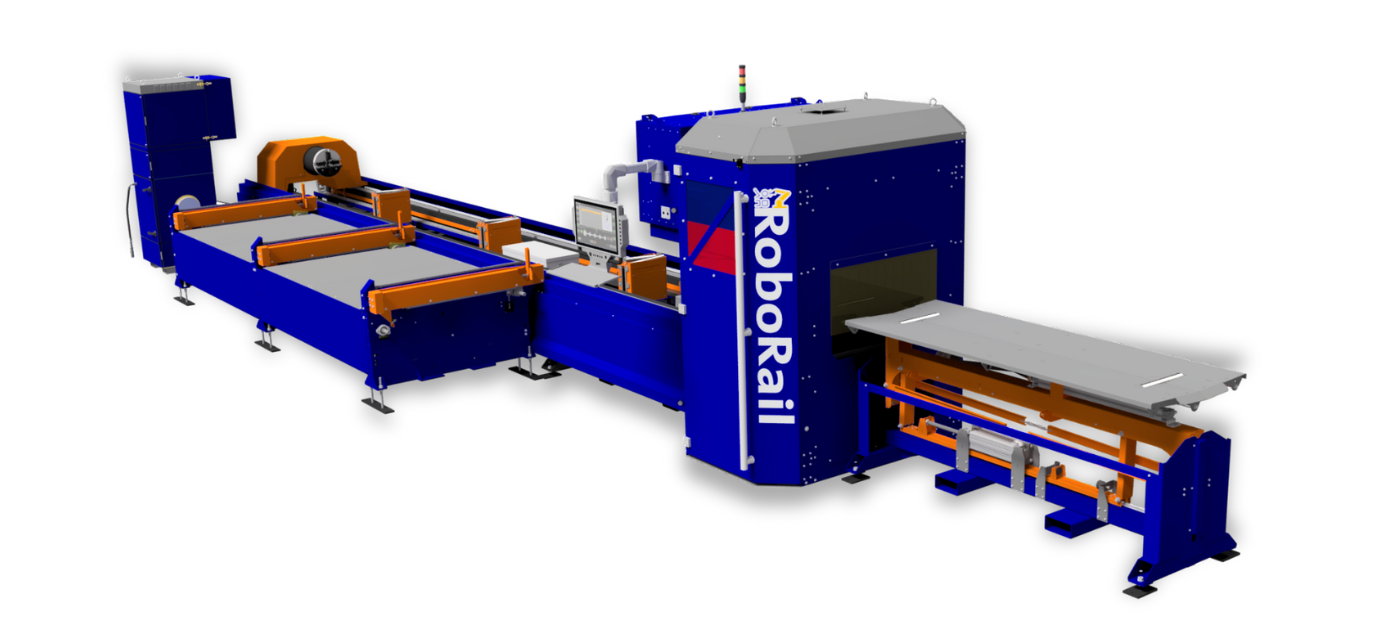

All-in-one robotic plasma cutting machine with a compact footprint

WATCH VIDEO

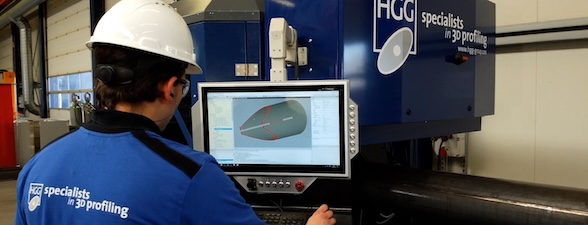

The all-in-one robotic plasma cutting machine

The all-new RoboRail will give you a more robust, reliable, and flexible solution you have always been looking for. HGG is the world leader in 3D profiling technology, and we have developed the new RoboRail in partnership with Automated Layout Technology, LLC to process a vast range of material quickly and accurately to length: cuts, copes, holes, layout marking, and more. Handrail pipe, stringer channels, box tubes, and angles are processed with a state-of-the-art Stäubli robot and reliable Hypertherm plasma system.

Specifications

Profile & Dimensions

- Profile

- Minimum

- Maximum

| 25 mm | 250 mm | |

| 25 x 25 mm | 200 x 200 mm | |

| 50 x 38 mm | 280 x 95 mm | |

| 25 mm | 200 mm | |

| 50 x 10 mm | 280 x 20 mm |

| 1 “ | 10 “ | |

| 1 x 1 “ | 8 x 8 “ | |

| C 3 x 4,1 “ | C 12 x 30 “ | |

| 1 “ | 8 “ | |

| 3-7/8 x 1/4 “ | 11 x 3/4 “ |

Additional Specifications

- Plasma cutting

- Plasma marking

- CAD Connection

- Material thickness between 3 - 20 mm or 1/8 - 3/4 inch

- Infeed length/weight limited to 7.135 mm / 400 Kg 24 ft / 882 Lbs

- Outfeed length is limited to 2.500 mm / 8 ft

- Minimal flatbar thickness is 10 mm / 3/8 inch

Discover the possibilities of the RoboRail

Cutting Compensation

Our software compensates automatically for the shape of the plasma arc resulting in and accurate and perpendicular cut.

Cutting of Bars, Channels and Hollow Sections

The RoboRail is a highly versatile machine for all your miscellaneous metals, including pipes for handrails.

High Quality Hole Cutting

Cut holes and slot holes, even on thick-walled profiles.

Marking Options

The RoboRail support both text and line marking for easy fitting.

Cut profiles and hollow sections with one machine

The RoboRail has the best of both worlds. A chuck for cutting the hollow sections by rotation. And a Staubli robot arm which gives the freedom to cut profiles without the need for rotation. One machine for copes, notching, cut-outs, holes, slot holes and markings.

Streamline Production with CAD Integrations

The RoboRail will let you work with DSTV and STEP-files directly from CAD-systems like SDS/2, Tekla Structures, SolidWorks, Inventor and many more. This will drastically reduce processing time and eliminates human error. With the RoboRail each and every piece can be different, and the machine will continue to process by reading files directly from your detailing. You can sit back and let the interface of the RoboRail guide you through the process.

Automatic Infeed and Outfeed

The RoboRail can be supplied with an infeed table which simplifies the material handling and guarantees a higher ‘burner on time’.

Standard features include an outfeed table for short parts, which takes all the finished parts from the cutting cell and tilts them into a crate. Longer parts can be fed out onto a roller conveyor.

3D Profiling Shapes

Automated Pipe Cutting

From handrail to medium sized truss structures, the RoboRail can do it all. In a matter of seconds.

- Plasma Cutting

- Plasma Marking

- Material 25 - 250 mm or 1 - 10 "

Automated Angle Cutting

The option to cut angle profiles gives you extra flexibility to complete any miscellaneous work.

- Plasma Cutting

- Plasma Marking

- Material 75 - 300 mm or 1 - 8 "

Automated Channel Cutting

The RoboRail is the best in processing stair stringers, platform reinforcement structures.

- Plasma Cutting

- Plasma Marking

- Material up to 280 x 95 mm or 12 x 3-1/8 “

'From having five or six guys processing parts that take 10 minutes each, to a single operator machine that’s doing them in 40 seconds, is kind of a no brainer.'

Peter Griffin, Owner at Griffin Welding