Case Study RoboRail

HGG Case Study at SL Chasse Steel

WATCH VIDEO

About this case

Introduction

Miscellaneous metal fabrication can be a tedious part of fabrication. You have to be precise; you have to be accurate, or things just won’t fit. Traditionally stair stringers would be laid out using a soapstone, pipe would be processed in a cold saw and then nudged in a punch press.

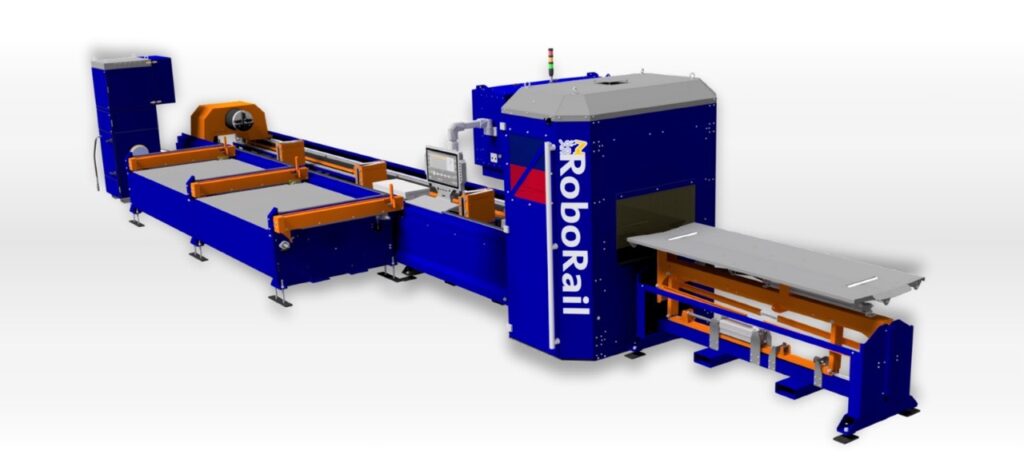

Together with Automated Layout Technology, HGG created the RoboRail with the aim to transform the production process of miscellaneous metal.

3

Times faster production

RoboRail

2022

Installation date

RoboRail

175+

Employees

SL Chasse Steel

1989

Established in

SL Chasse Steel

Transforming fabrication

SL Chasse Steel, a structural steel fabricator and miscellaneous metal fabricator based in Hudson, New Hampshire, was one of the first companies to incorporate the machine into their production process.

Stephan Chasse, President and owner of the company: “We now produce miscellaneous metal just like we do structural steel. All our fittings, all our parts are fabricated beforehand using the RoboRail. If for example, we will produce a railing we can now make sure that the parts are already cut. The holes are already there. Our fitters will use the Lightning Rail to layout a railing, take all the pieces and parts from the RoboRail, build it right there on the Lightningrail. Fabricate. Get it off the bench and continue on.”

Streamline tedious work

Miscellaneous fabricators have a set of challenges that require automation. Every item can be a unique one-off piece whether it be your stair stringers, pipe for your railings or channels for your headers. A common misunderstanding with fabricators is that this makes automation impossible. At HGG we believe that this is exactly what makes automation so important. Letting the RoboRail be the workhorse in your shop and let your craftsmen focus on what they do best.

“At SL Chasse Steel we realized quickly that we could fabricate misc. metals just like we do structural steel. So we can get all our parts done first. Get all our stringers done first. We can process al our pipe first. And then feed the fitters just like we would do in structural steel. And it’s the same philosophy. You can get a large amount of product out quickly and done correctly by using a machine like this.”

“You are going to get 3 times more product out in the same amount of time using a machine like the RoboRail. 3-times product. 3-times volume. 3-times more money really is what it comes down to.”

Stephen Chasse, President, SL Chasse Steel