HGG Cutting Services

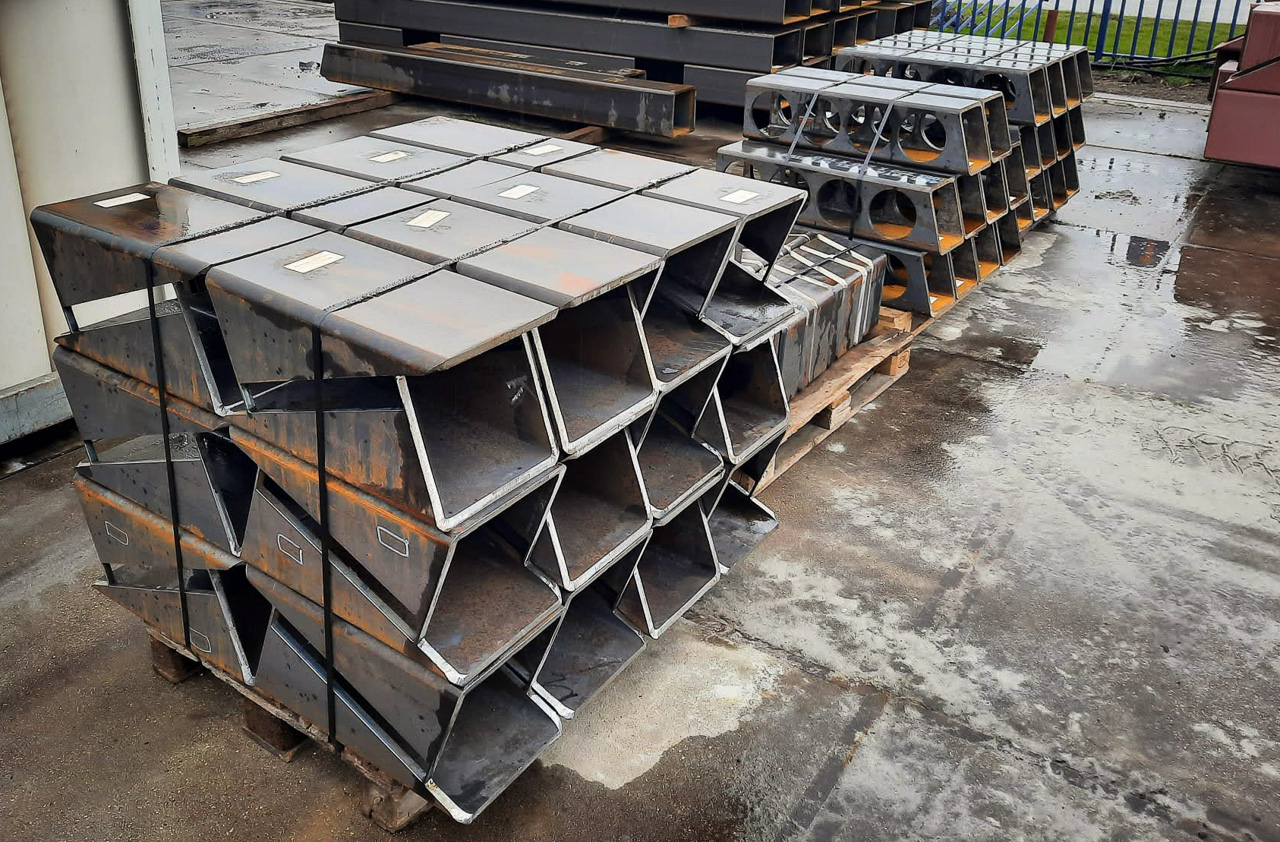

Box cutting services

Description

We specialize in precision cutting of square and rectangular box profiles for a range of industries, including infrastructure, offshore wind, process industries, and steel construction. Our cutting process ensures accuracy and allows for additional features such as welding edges, round holes, and various shapes.

By choosing HGG for your box sections, you can achieve flawless connections with other box profiles, pipes, or sheet material. Our capabilities span from small to large dimensions, and we can handle material lengths of up to 24 meters with ease.

Specifications

Width, thickness & tolerances

Min. 25 x 25 mm. – Max. 600 x 400 mm.

Wall thickness

Min. 3 mm. – Max. 40 mm.

- Endcut and intermediate cut tolerance ± 2 mm, up to and including a thickness of 25 mm.

- Endcut and intermediate cut tolerance ± 2 mm plus 0,02 x thickness, from a thickness of 25 mm.

- Endcut and intermediate cut tolerance ± 5 mm from a pipe diameter Ø2500mm or conical tube

- Distortion tolerance of a cut ± 2 mm, measured on the inside of the hollow section with respect to the reference line.

- Length tolerance is 2x endcut tolerance plus 1/10.000 from length of the pipe

Need assistance or advice?

Receive a targeted advice and proposal based on your situation and wishes.

Box Cutting Services

This is why our clients choose us:

- Time and cost-saving

- Unmatched accuracy

- Dedicated support

Contact our specialists

Sales Engineer

Ad Rietveld

- (+31) 6 233 898 64

- a.rietveld@hgg-group.com

- Noord-Brabant, Zuid-Holland, Zeeland (NL), Belgium, France

Sales Engineer

Bart Meijer

- (+31) 6 211 254 17

- b.meijer@hgg-group.com

- Limburg, Noord-Holland, Noord-Brabant, Utrecht (NL), Scandinavia, United Kingdom

Sales Engineer

Arthur Schouten

- (+31) 6 273 583 84

- aps@hgg-group.com

- Drenthe, Flevoland, Friesland, Gelderland, Groningen, Overijssel (NL), Germany

Sales Engineer

Rodelyn Tuazon

- (+63) 822 824 500

- rodelyn@hgg-asia.com

Area Sales Manager

Ed Macdonald

- +1 (346) 314-9659

- e.macdonald@hgg-group.com

- (Western) North America

Contact HGG

Contact HGG

- (+31) 227 504 030

- info@hgg-group.com

- Europe

Sales Engineer

Rodelyn Tuazon

- (+63) 822 824 500

- rodelyn@hgg-asia.com

Sales Engineer

Rodelyn Tuazon

- (+63) 822 824 500

- rodelyn@hgg-asia.com

Area Sales Manager

Ed Macdonald

- +1 (346) 314-9659

- e.macdonald@hgg-group.com

- (Western) North America

Contact HGG

Contact HGG

- (+31) 227 504 030

- info@hgg-group.com

- Europe

Sales Engineer

Rodelyn Tuazon

- (+63) 822 824 500

- rodelyn@hgg-asia.com

Why choose for HGG?

Reliable partner with 40 years of experience

HGG has been cutting profile steel, such as tubes, beams and tubes, for decades with its own developed machines and software.

Short lead times and a large capacity

With our modern machinery with a large range, HGG takes care of all your profile cutting work within the requested delivery time. Due to our large storage area and machinery, HGG has a large capacity.

The solution for your staff shortage

HGG is active in various industries and takes a lot of manual work off your hands by cutting a wide variety of profiles, making it an extension of your workshop.

Tailor-made for all your profiles

With our advanced software, we cut any desired shape, resulting in less fit time, welding volume and welding time. You will receive a complete construction kit from us, including the desired welding pre-treatment and any markings and fit lines.

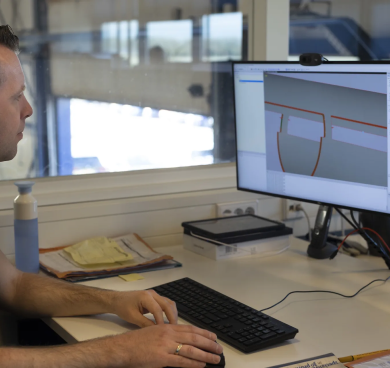

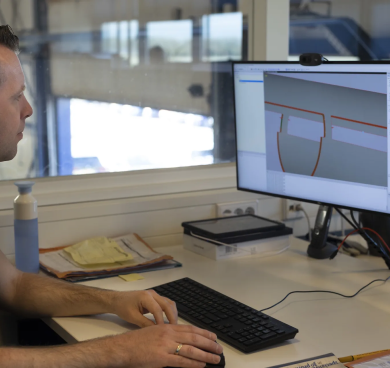

Our 4-step process

We take the weight of your shoulders with a simple and clear 4-step process that ensures quick delivery and meets the highest industry standards.

Specialized advice in advance

From our 40 years of 3D profiling experience, we know that every cut can be different. We assist you in the preparation of your project. From engineering, to welding details to optimizing material usage.

Get your quote

Based on your data, preferably in STEP format, we send you a tailored project quote within a few days of your request. If you regularly outsource projects with us, we are eager to take it a step further by establishing a partnership. Assuring you with production capacity and price stability.

Start Work Preparation & Production

After receiving your final models and material we will prepare cutting files using our ProCAM software. Once these files are ready production will be started at our production facility using the machine which suits best to the materials that need to be cut.

Pick-up or get your shipment delivered

After completion of the cutting job, you will receive a message that your materials are ready to be picked up. If you need us to deliver the materials to your site we will make those arrangements.

'The HGG is the best machine. I think it's the best machine in the group and I think it's the best machine in the world.'

Dick Thornton - Southern Queensland steel

Our additional services

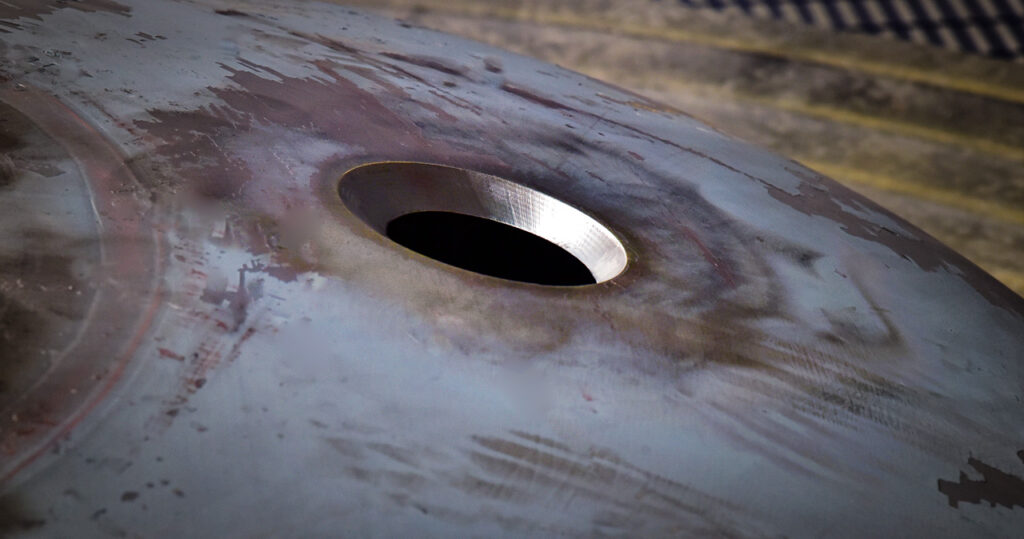

Additional Holes and Slots

In addition to the final cuts, we can add holes and slots for various applications. These can also be prepared with the desired welding preparations, such as a ½ V-groove or X/K-groove.

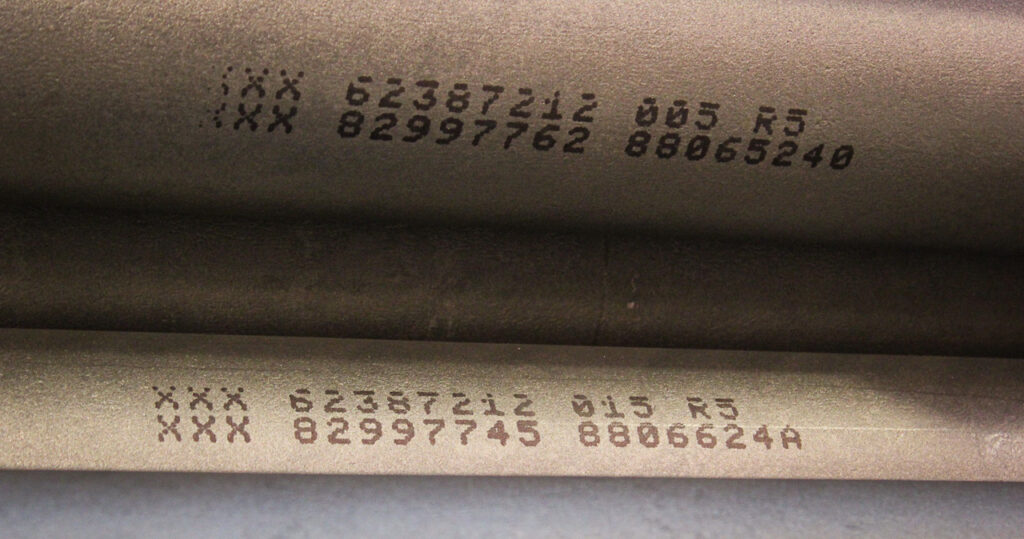

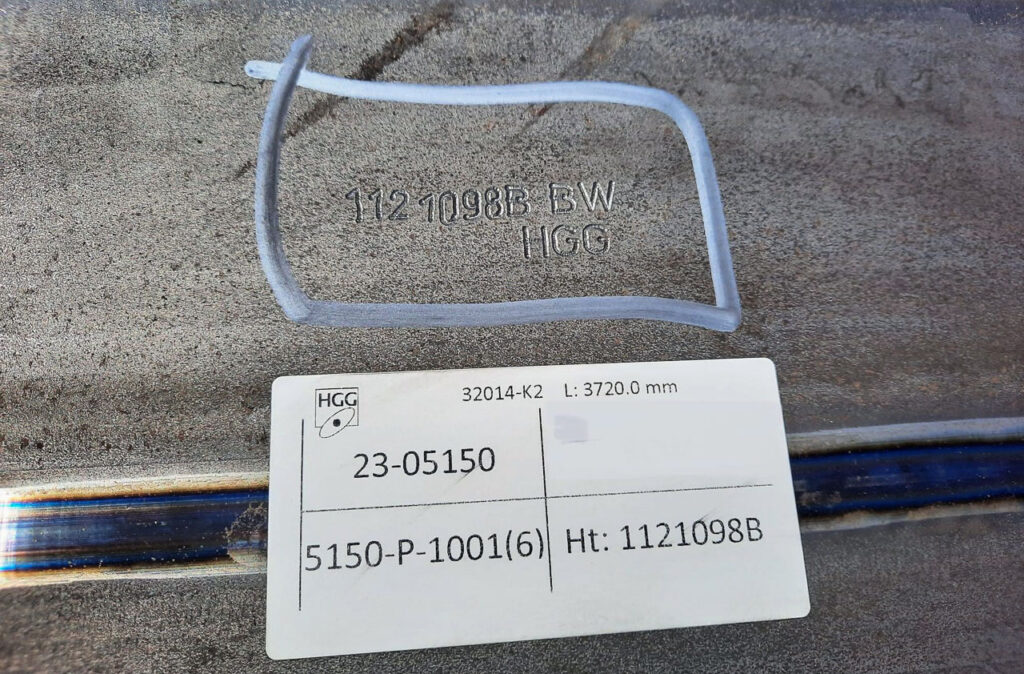

Adding Reference lines and Markings

Our machines can apply reference lines and footprint markings using either a needle or plasma. This not only speeds up fitting time but also ensures higher quality. By incorporating these markings into your engineering plans beforehand, we can replicate them directly in our production process.

Certified for Re-marking

We are certified by Lloyd’s Register Nederland B.V. to transfer markings and numbers and issue inspection reports 3.1 and 3.2 in accordance with EN 10204:2004.

Delivery, Storage & Transport

Materials are usually delivered to us by you or your supplier. We have a large storage area capable of accommodating large-diameter and long-length material. However, we can also arrange transportation for you, ensuring materials are picked up and returned to the desired location. We partner with a transportation provider who offers daily services both within the Netherlands and internationally.

Our accreditations and memberships

Our drawing guidelines

We are flexible with our drawing guidelines; however, we do prefer the options listed below for a speedy process. If you have a different file format or need assistance in preparing your files, feel free to contact our team.

STEP (3D)

We convert STEP files into cutting files with HGG’s ProCAM. Our system reads STEP files in freeform shapes without relying on macros, providing you with design freedom.

- For round tube: Closed Contour

- For square tube: Inside radius + Wall thickness = Outside radius

- Parts must contain only one solid

- No root faces <2mm

- No gradient root face

DSTV (2D)

No extra post-processor is required because HGG’s ProCAM can import and read data for DSTV (NC/NC1) files. Enriched files, with a 3rd party post-processor are also possible.

- Possible for Beams

- Possible for Box

- Possible for Profiles

- Not possible for Pipes

Need assistance or advice?

Give me a call or sent us an email with your challenge.