Case Study ProCutter 600 - 900

HGG Case Study at Mastenergo

WATCH VIDEO

About this case

introduction

Mastenergo is specialized in the production of antenna-mast constructions for telecommunications and digital television. Mastenergo received an order for a challenging large scale project – fabricating a tubular mast of 275 meters high digital television tower in Perm, Russia. In the past Mastenergo relied heavily on cutting with a saw and drill line and often used angled bar with simple connections or bolted connections and solid bar profiles in their works.

1

Machine

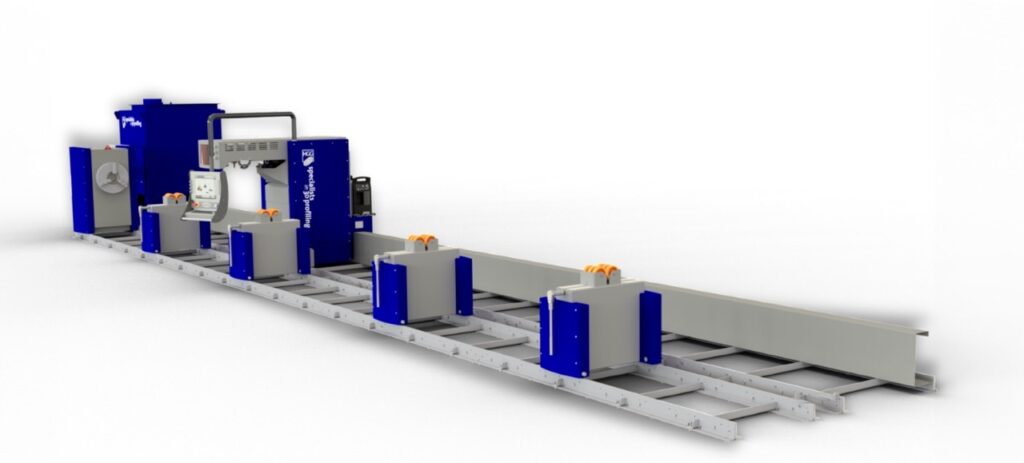

ProCutter 600 - 900

2006

Established in

Mastenergo

Perm tower solution

Soon after receiving the ambitious Perm tower project with such a complex geometry with bevels Mastenergo came up with a solution to the design challenge. Mastenergo’s idea was to implement separately fabricated nodes, each having a range of connecting members attached, which can be bolted later on during the erection stage. There was still one challenge remaining, though, and it was how to realize all the cutting with a bevel using a saw and drill line.

Efficiency with ProCutter 600

Having realized that they need an automated cutting solution for implementing those ambitious design and fabrication plans, Mastenergo purchased the HGG CNC Pipe Cutter ProCutter 600.

The structure for the Perm tower project, including all detailing of the weld geometry, was designed and detailed in Tekla Structures. Thanks to the cooperative HGG – Tekla software connection all parts were successfully exported to the HGG ProCAM framework, thus creating seamless integration with the HGG pipe cutting machine. Thanks to the various smart weld preparation techniques the ProCutter 600 applies, the quality of the cuts with a bevel was extremely high: “Compared to manual cutting the cuts coming out of the ProCutter 600 are way better. The cuts are cleaner and prepared for fast and easy welding.”, concludes Mr. Kuragin – a welder at Mastenergo with more than 40 years of experience.

“Very soon into the project we knew that such kind of complicated geometry with bevels is practically impossible to cut manually. You can work with templates but the result will be dirty which will lead to unavoidable geometrical distortions in the assembly.”

Mr. Soranov, Managing Director at Mastenergo