Often two separate machines are being used for sawing and hole cutting or drilling of beams. In this article you can read how bolt hole cutting is possible using an (HGG) Beam Cutting Machine.

Cutting a beam end needs a sequence of cuts covering both flanges and the web. Every shape is different and needs a unique sequence of cuts and combination of cutting techniques. Automatic determination of these combinations and techniques is called ‘cutting intelligence’. Often a CNC Beam Cutting Machine can determine the correct sequence and necessary techniques itself.

HGG’s RPC Beam Cutting Machine is developed to combine processes in one machine. “Is it possible to cut bolt holes with a similar accuracy?” is often asked. It is possible, using the PerfectHole™ Technology.

PerfectHole™ Technology

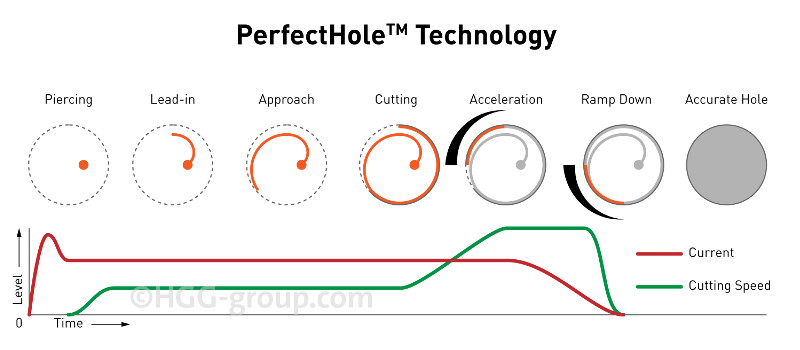

Cutting of a perfect bolt hole starts with a circular path. HGG’s real time control of all required robot axes ensures a fluent circular path of the cutting torch. A combination of cutting techniques is selected to cut holes perpendicular. Kerf width compensation, arc shape compensation, optimized cutting direction and a special lead-in and lead-out are the base of this technology. PerfectHole™ Technology leads to a perpendicular, circular and gouge free hole according to EN1090-2 and AISC standards.

PerfectHole™ Technology, as shown in the image below, compensates the arc shape behavior during cutting. The applied lead-out technique prevents increasing of the arc length after the scrap piece dropped out which enables a non-gouging arc ramp down for a long consumable lifetime and a gouge free bolt hole.