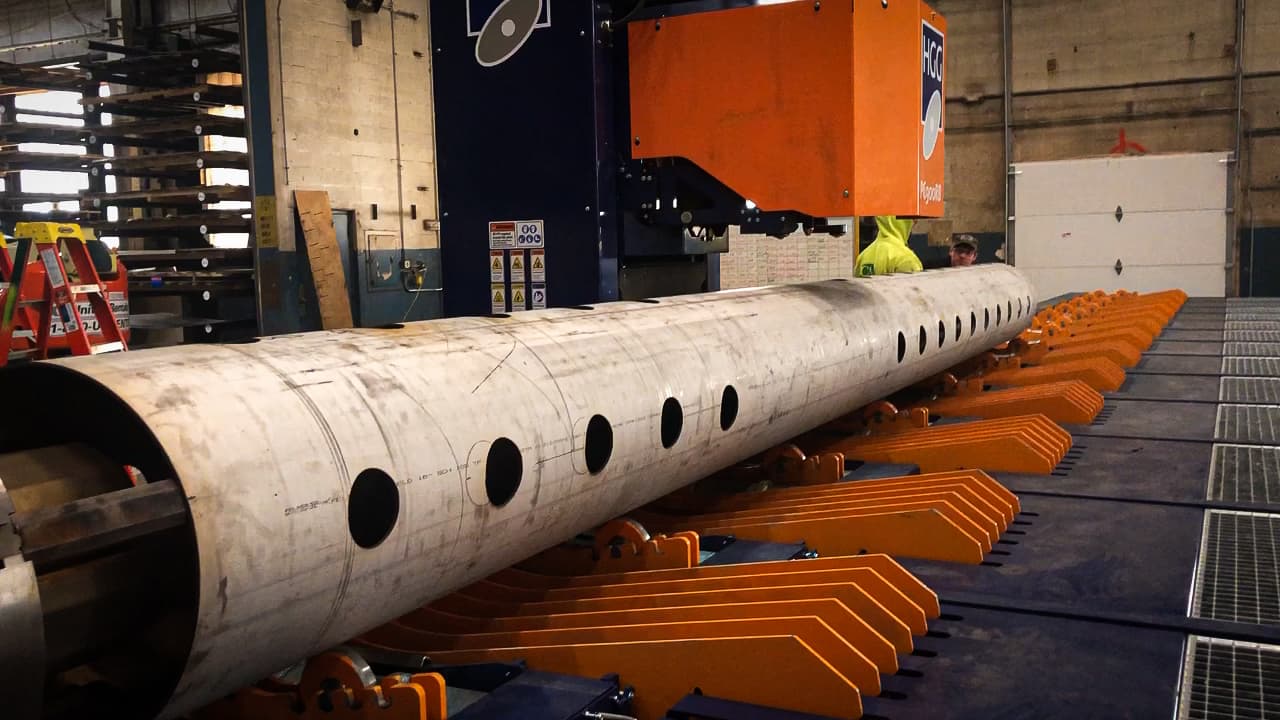

Join our US-based Area Sales Manager, Todd Wellens, for a tour of our heavy-duty pipe profiler, the ProCutter 900 RB. This Pipe Cutting machine was developed in collaboration with one of our major mechanical contractors in the United States. They needed a versatile solution that would fit seamlessly into their shop while still handling a wide range of materials. The ProCutter 900 RB delivers exactly that, efficiently processing large volumes of pipe to keep welders supplied and productivity high. In this video, we’ll highlight the key features that make this machine stand out.

Watch the video

The smaller footprint, its lower investment level and ability to process a lot of pipes in a very short amount of time makes this machine ideally suited for mechanical contractors, the oil and gas sector, structural steel projects, and the offshore industry.

Developed in collaboration with a mechanical contractor, the ProCutter 900 RB is designed for high-speed pipe processing, quickly moving pipes through the shop to feed the welders. It automates the transfer of pipes from (outdoor) storage to the cutting area, where they are clamped securely in the chuck. Once the pipe is fully cut, it is automatically unloaded onto a storing surface for operators to collect, streamlining the workflow and enhancing efficiency.

With a patented pantograph cutting head

We are committed to delivering a top-quality machine designed for durability and long-lasting performance. This is shown not just by equipping the machine with a robust five-and-a-half-ton chuck but also in our patented pantograph cutting head. This innovative feature enables a full 360-degree pivot and 45-degree beveling, offering you unparalleled design flexibility.

Equipped with a Two-Point Fume Extraction System

Efficient fume extraction is essential for operator safety and the longevity of the machine. The ProCutter 900 RB features a two-point fume extraction system.

The primary extraction point is located within the pipe itself and exits through the main drive. Fumes inside the pipe are routed through a dedicated exhaust point integrated into the main drive unit of the pipe cutting machine. This system includes a spark collector connected to a dust tray, ensuring easy collection and cleaning.

The second extraction point is positioned near the cutting process on the cutting trolley. This is specifically designed to enhance operator safety, utilizing a suction system to direct fumes to the main extraction system located behind the main drive.

Easy connection with a.o. Solidworks, Revit, Pypeserver, M-Suite and Stratus

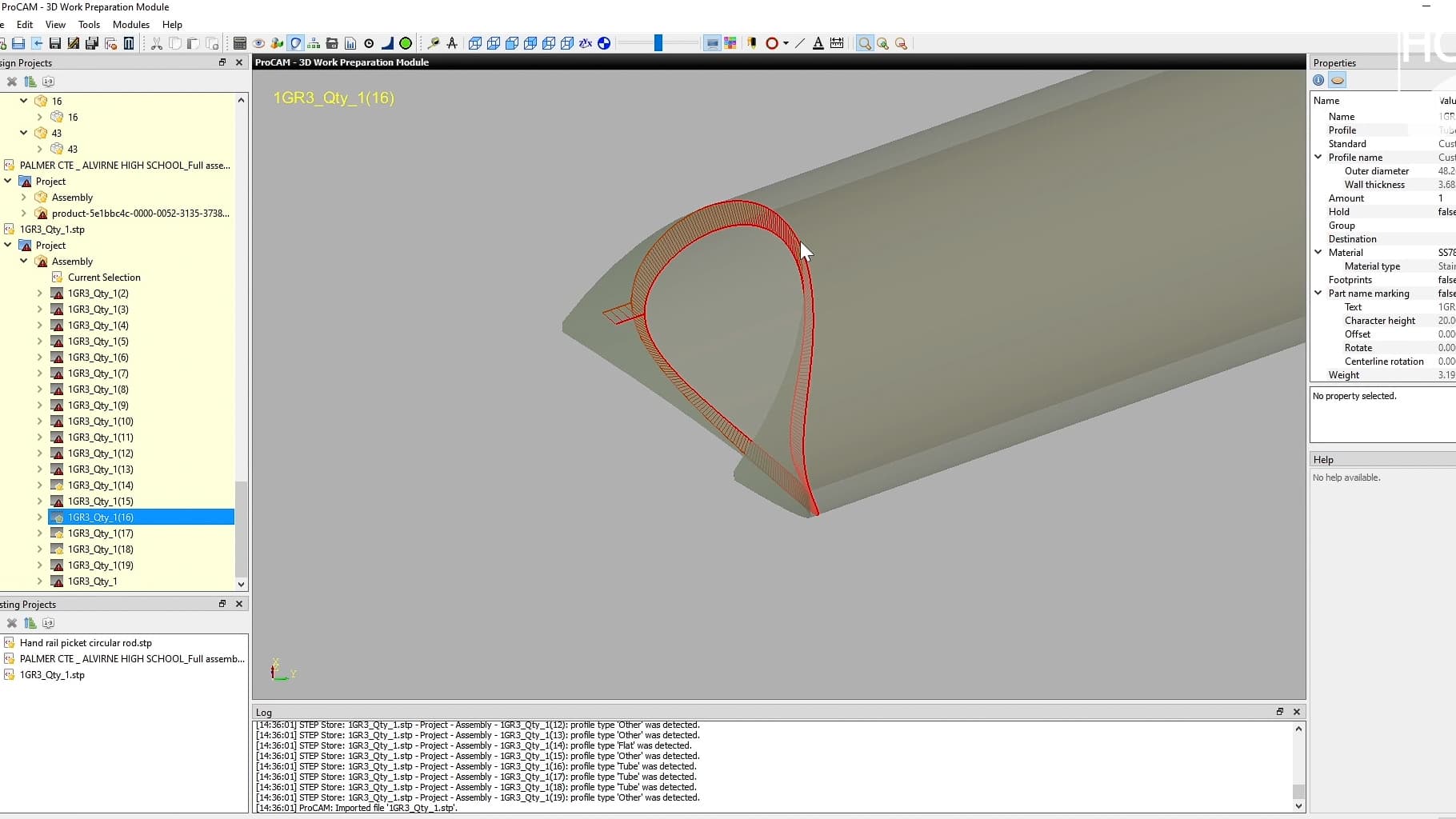

We don’t just focus on building the best machines; at HGG, we also invest in developing top-tier software. Our dedicated team has created ProCAM, a software solution designed to seamlessly import files, generate CAM programs, nest components, and execute these nests flawlessly on our machines.

We collaborate with a wide range of software companies to ensure compatibility and efficiency. This includes working with 3D CAD platforms like SolidWorks and Revit, as well as specialized software providers such as PypeServer, MSUITE, and Stratus.

Are you ready to transform your business into a true manufacturing powerhouse? Experience consistent cutting quality and efficiently move your pipes through the shop with HGG’s ProCutter 900 RB.