Lack of control on upwards and sideways movements of heavy pipes can influence the accuracy of your cuts. Read this article to discover how FitPerfect™ Technology is developed to solve these challenges.

Heavy pipe distortions and deviations, such as bow shape and out of roundness, will influence the accuracy of cut holes negatively caused by inaccurate material positioning. Swing occurs during rotation of a deviated pipe which lays on pipe supports. There is no control of upwards and sideways movements of the pipe, which leads to inaccurate cuts.

FitPerfect™ Technology uses an extra axis for transversal movement to perform the cutting of holes without pipe rotation. The transversal axis can bypass the causative pipe rotation during cutting and use FitPerfect™ Technology.

Perfect round holes on shells and heads with FitPerfect™ Technology

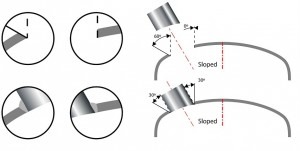

HGG’s advanced FitPerfect™ cutting technology is highly recommended for pressure vessel and vessel head cutting. FitPerfect™ Technology and cutting compensation ensure highly accurate hole cutting on both shells and heads. The longitudinal and transversal axis are able to create a perfect circle in one plain. The height axis adjusts the cutting torch to the fluctuating level of the material surface. The AutoFocus robot is responsible for the beveling along the path. This approach safeguards a perfect circular hole. The result is a perfect and equal weld preparation along the full fit line of the nozzle-hole connection.

- Provides constant root opening

- X bevel for K weld preparation

- No grinding prior to welding

- Less welding time and volume

- No more rejections