Case Study SPC 500 - 1200 PT

HGG Case Study at Sedong Precision Co., Ltd

WATCH VIDEO

About this case

Introduction

Sedong Precision Co., Ltd, based in Gimhae-si, Republic of Korea, has been manufacturing parts for the shipbuilding industry for over 35 years. Producing products that need to withstand the harsh marine environment, such as corrosion and high temperatures. These types of jobs require a rigorous and labor-intensive production and quality control process to ensure safety and meet industry standards.

To improve efficiency in the process, Sedong turned to HGG for the cutting of their pipes.

2

Machines

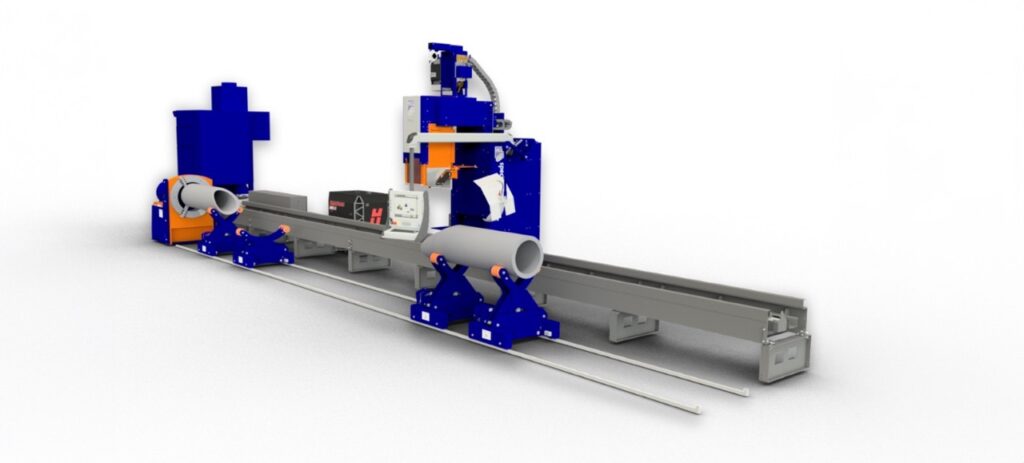

SPC 500 - 1200 PT

2023

Installation date

SPC 500 - 1200 PT

50%

Reduction manual work

Sedong Precision Co., Ltd

1989

Established in

Sedong Precision Co., Ltd

Reducing Loss with Automation

Back in 2015, Sedong and HGG first connected, resulting in the installation of the SPC 600. Having used that machine for a couple of years, they opted for its bigger brother, the SPC 1000.

Oh Sang-tae mentioned, “We have been using HGG equipment for a long time and have been able to reduce massive amounts of loss due to automation. Initially, we were a bit worried since the machine is foreign equipment, but having VNI, HGG’s local Korean partner, took our worries away.”

Cutting Down Manual Work by 50%

With the equipment, Sedong now saves time and money on more than just the process of cutting their pipes. In the shipbuilding industry, with its demanding standards, many benefits come at the welding and inspection phase of the production. “We have been able to reduce manual work by 50% with the HGG machine because the cutting quality is so good that you don’t need to check the product for any cutting errors.”

Director Oh Sang-tae is confident the new SPC machine will quickly find its place in the company: “The software is very easy to use. Anyone can use it. And the machine itself is straightforward, easy to cut, and convenient for me to work with. We don’t think it will take long to make back the money we invested in the HGG machine.”

“Due to the nature of engine manufacturing work, many parts are welded in a narrow space. After manufacturing, product inspections have to be completed. Because of the HGG machine and ProCAM, the product’s quality is very high, and manpower and time have been greatly reduced.”

Oh Sang-tae, director, Sedong Precision Co., Ltd