Case Study SPC 1500 - 4000 PT

HGG Case Study at Civmec

WATCH VIDEO

About this case

introduction

A focus on continual improvement and innovation, performance driven attitude and pursuit of excellence. These are some of Civmec’s core values that define their company. With 45.000 tons of steel going through their workshop every year, it is important to invest in 3D profiling equipment that can live up to the company’s standards and values. That is why Civmec invested in four HGG machines in the span of two years.

“The output we can get from the 3D profiling machines and the quality of the cuts as well is fantastic”, according to David Power.

4

HGG machines in 2 years

Civmec

2016

First machine installed

Civmec

45.000

Tons of steel processed annually

Civmec

1990

Established in

Civmec

Mastering Precision

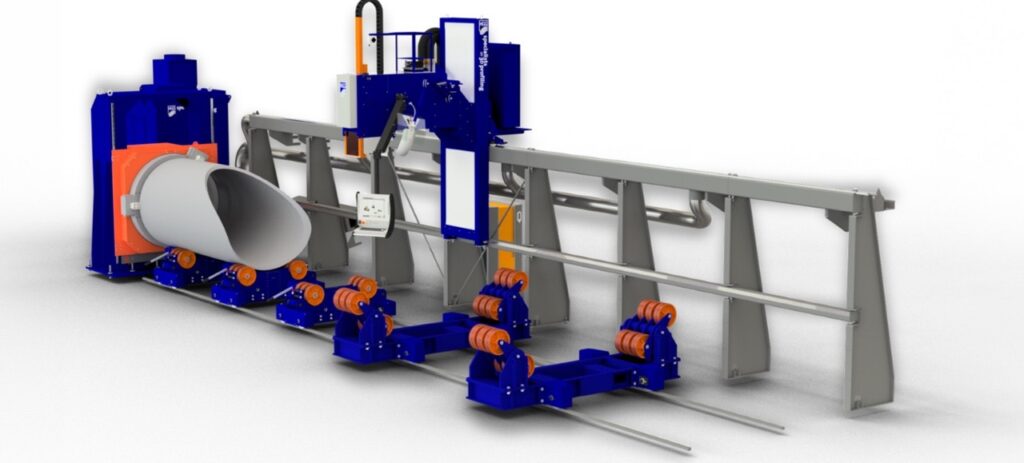

In September 2016, Civmec invested in their first HGG machine, the SPC2000 pipe cutting machine. Processing supervisor Norm O’Connel told us “The accuracy of the machine is spot on”. The company was very pleased about its result and invested in three more machines in the span of 24 months. Now the company is the proud owner of an SPC 1000, SPC 2000, PCL 600 and RPC 1200 which automates there cutting work. “The fit up is significantly less, because we don’t have to manually bevel plates, pipes or the beams. It is correct coming of the machine. It reduces the amount of man hours associated with fit ups for sure.” Mr. Power said. “We’ve got a remote access from HGG that are able to integrate into the machines so they can operate the machines from the Netherlands. Wherever we have an issue with the machines, there able to log on and figure out what is going on”.

Excellent product service

Besides being very pleased with the 3D profiling machines, Civmec also has a lot of appreciation for the HGG service. They know that HGG is working in their interest and are there to optimize the customer satisfaction and fulfill the company needs.

Civmec is very on-point about improving the company’s productivity and efficiency. That is why they have chosen to invest in HGG’s machinery. With two SPC’s running in their facility, the output became massive and made it able for Civmec to process the huge amounts of steel pipes.

Mr. Power told us: “The SPC2000 is a fantastic pipe cutting machine, obviously with the diameter of the pipes we can cut up to 2 meters diameter pipes. We have a fantastic output from the pipe cutting machines SPC1000 and SPC2000, it has increased our productivity massively”.

“With the implementation of the HGG machines we are able to cope with the plasma which is significantly faster and way more productive”

David Power, Facility manager