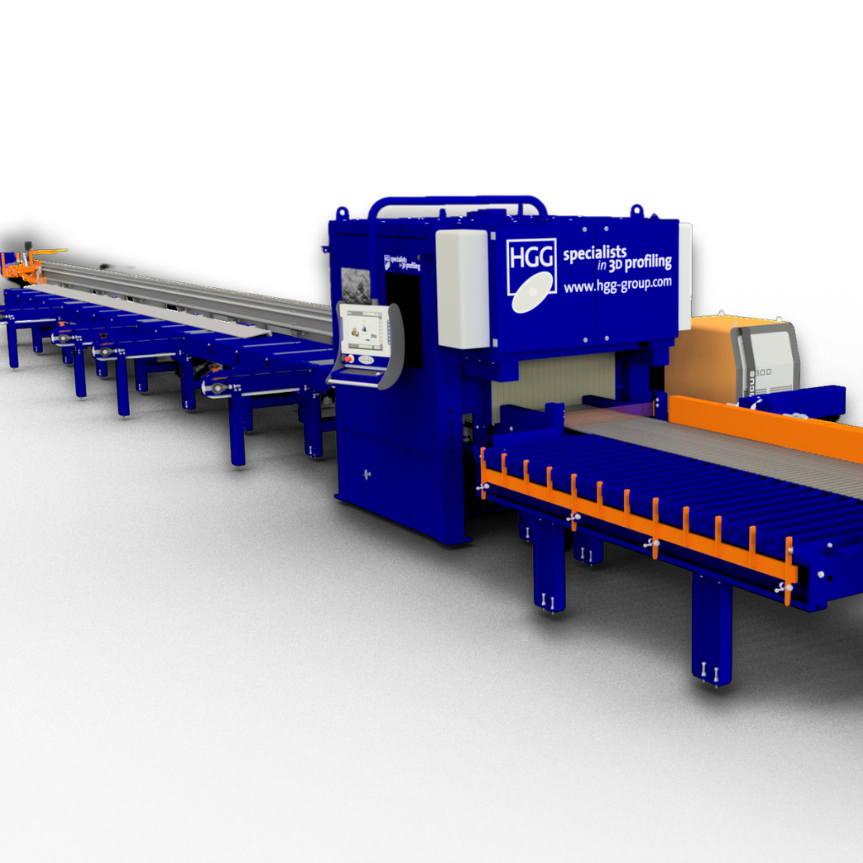

Product Tour PCL 600

The High Performance Robotic Stiffener Profile Cutting Line

WATCH VIDEO

World's Most Productive Profile Cutting Line

The PCL 600, or Profile Cutting Line, is specifically designed to cut stiffener profiles used in the shipbuilding industry. Equipped with a highly capable robot, it performs three-dimensional profiling, allowing for precise cuts with bevels and angularity, ensuring maximum flexibility and accuracy for complex shapes.

Specifications

Profile & Dimensions

- Profile

- Minimum

- Maximum

| 100 x 55 mm | 420 x 220 mm | |

| 70 x 25 mm | 420 x 150 mm | |

| 100 x 50 mm | 550 x 200 mm | |

| 50 mm | 220 mm | |

| 75 x 50 mm | 550 x 150 mm | |

| 60 mm | 430 mm | |

| 60 x 6 mm | 550 x 30 mm |

| 4 x 2-1/8 “ | 16-2/4 x 8-5/8″ | |

| 2-3/4 x 1 “ | 16-2/4 x 5-7/8 “ | |

| 4 x 2 “ | 21-3/4 x 7-7/8″ | |

| 2 “ | 8-5/8 “ | |

| 3 x 2 “ | 21-5/8 x 5-7/8 “ | |

| 2-3/8″ | 16-7/8 “ | |

| 2-3/8 x 1/4″ | 21-5/8 x 1-1/8 “ |

Additional Specifications

- Plasma cutting

- Plasma marking with cutting torch

- Powersource: Hypertherm or Kjellberg

Discover the possibilities of the PCL 600

Highly Productive

The PCL 600 is the most productive profile cutting line on the market, without compromising on accuracy.

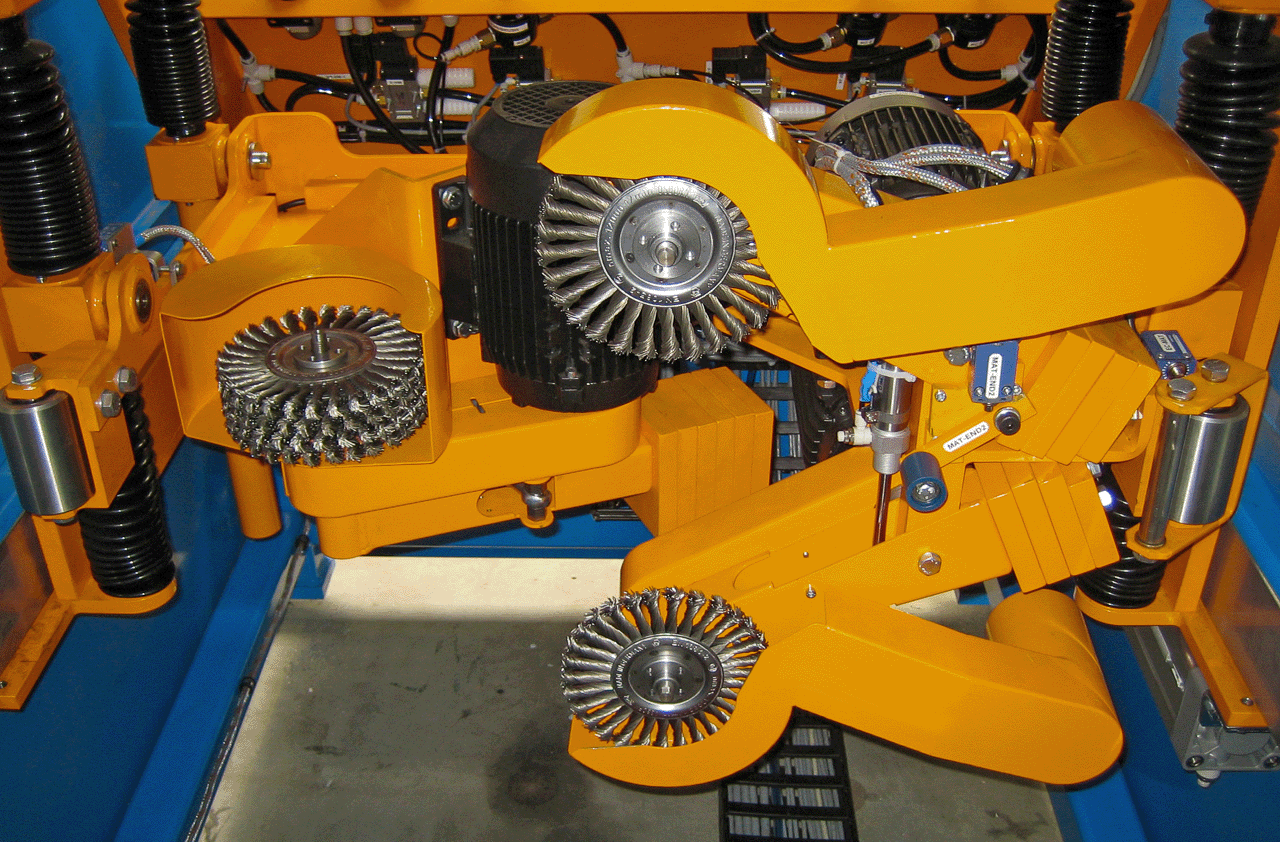

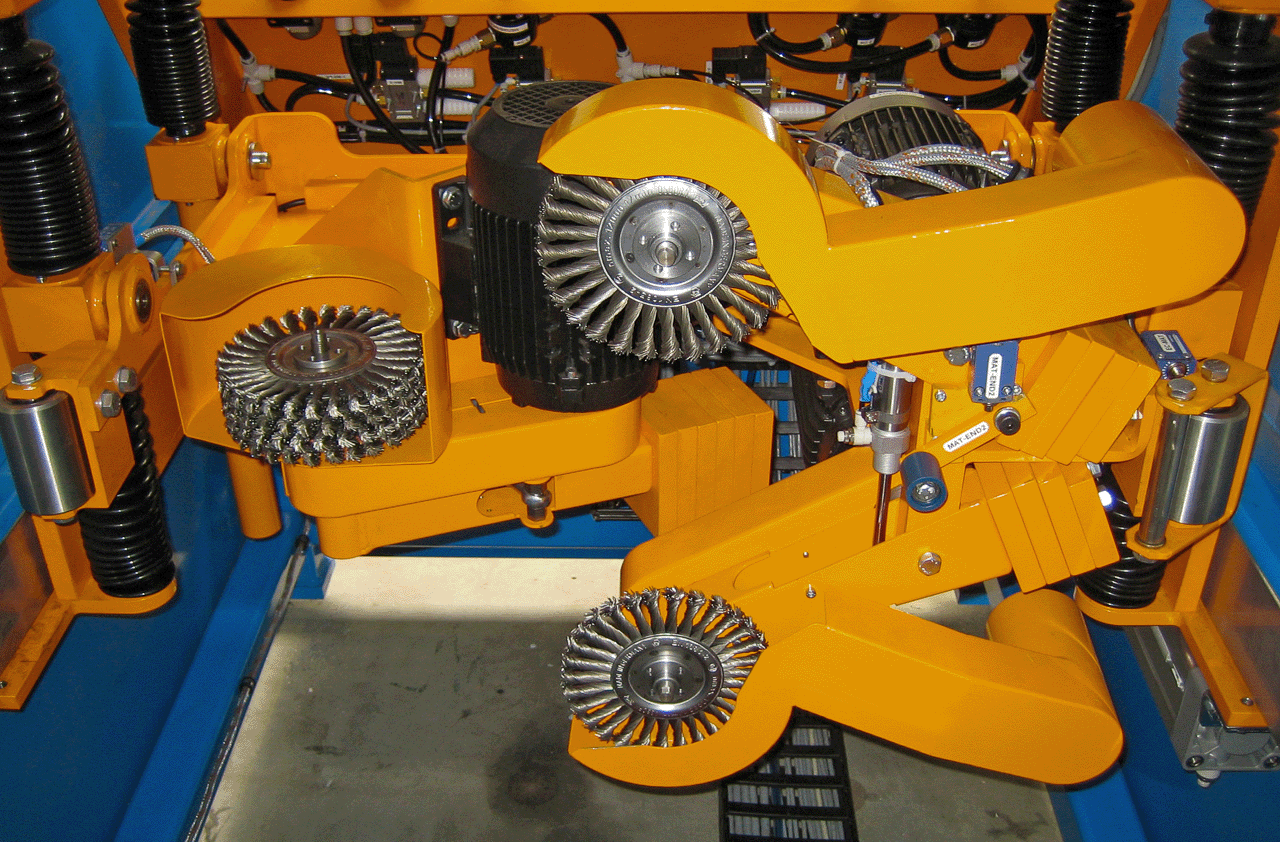

Edge Cleaning

Combine HGG’s profile cutting line with an edge cleaning unit, which cleans the foot of the profile, enabling high-speed automated welding.

Bendline Marking

Inkjet marking is supported for the marking of text, reference lines, and inverse bend lines, simplifying stiffener bending.

End-cuts, cut-outs and holes

Cut any shape on stiffener profiles, with or without weld preparation.

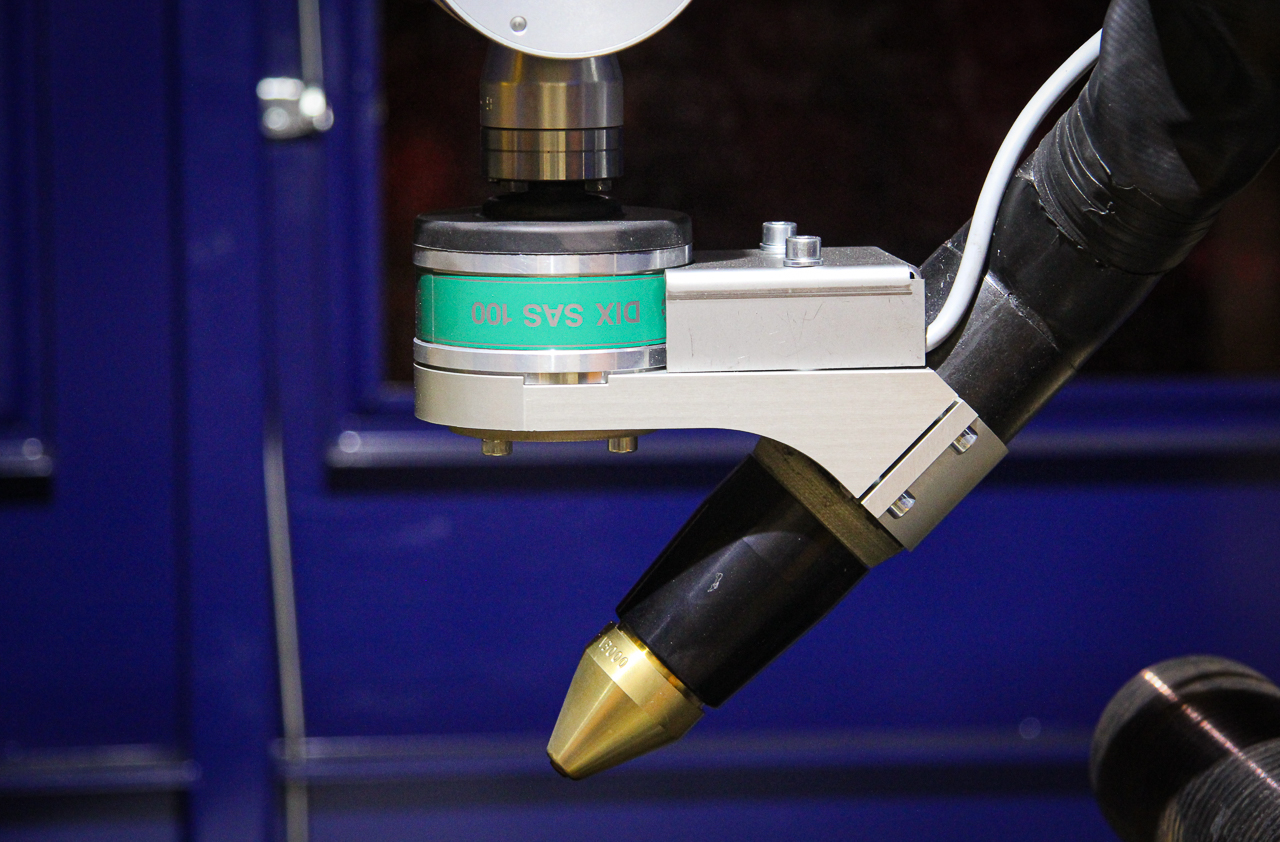

Cut your profiles with plasma

HGG has distinguished itself as a pioneer in CNC plasma cutting. Since 1994, HGG has supplied over 500 3D profiling machines with plasma cutting technology worldwide and keeps innovating with plasma cutting technology to stay on top of the latest developments.

HGG offers unique features that further improve the quality of plasma cutting by compensating for plasma characteristics and/or prolonging consumable lifetime.

We support both Kjellberg and Hypertherm plasma sources. Two well experienced and industry leading choices.

Integrated Edge Cleaning Unit for faster and better welding

An Edge Cleaning Unit (ECU) provides simultaneous triple edge cleaning. Most fabrication codes demand that potential contaminants are removed from the welding zone and an arbitrary distance away from the anticipated toe of the final weld. HGG provides brush units and shot blast units that clean all three faces of the material. These machines are specifically developed for the purpose of cleaning stiffeners at variable angles and are incomparable to a flat plate or strip cleaning machine.

The advantages of edge cleaning:

- Faster welding

- Higher quality welding

Powerful CAD-CAM connections made by our in-house software team

Our software integrates seamlessly with all major CAD systems in the shipbuilding industry, including ShipConstructor, Bocad, Aveva, and Nupas Cadmatic.

Do you have specific CAD-CAM integration needs? No problem. With our in-house software team, we can quickly adapt, develop, and release the necessary updates.

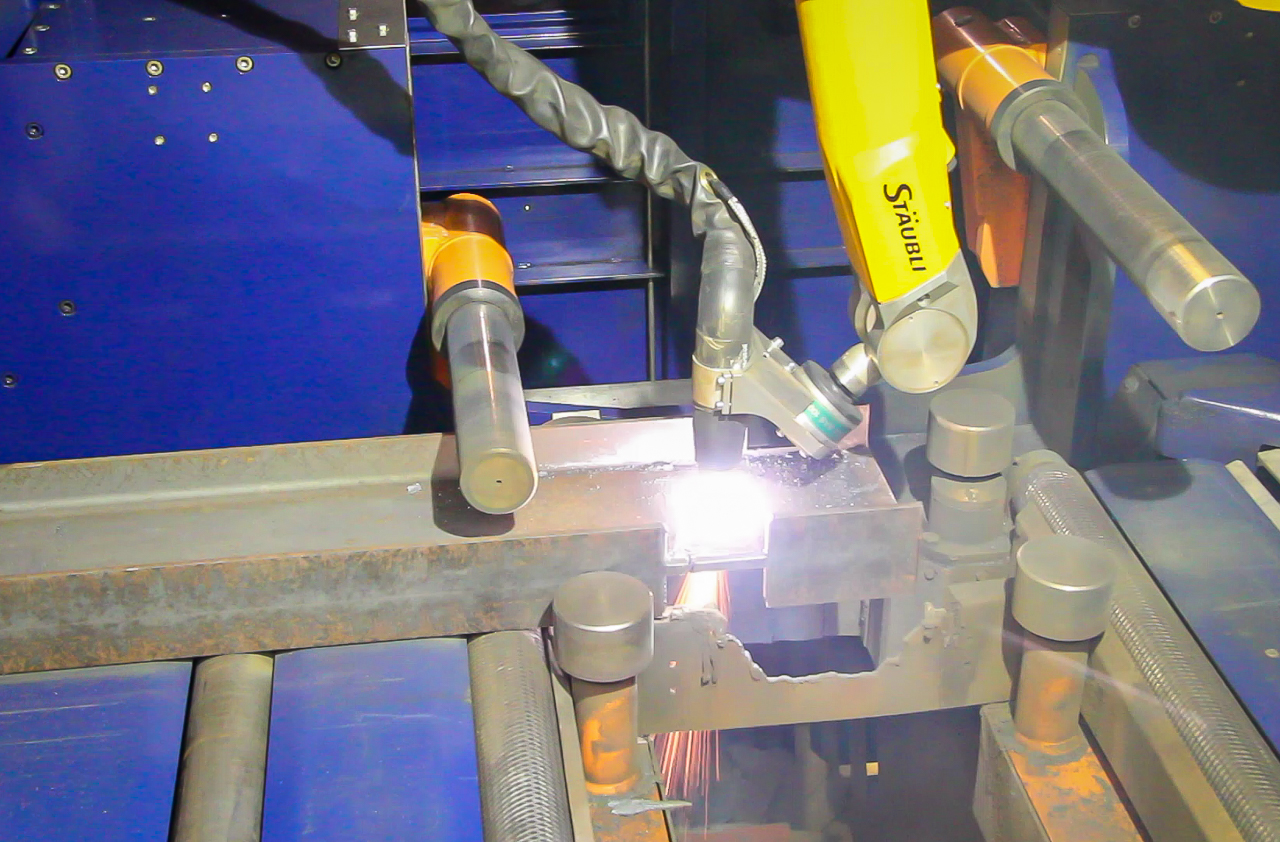

Seamless Integration of Cutting and Welding Solutions

Our cutting solutions integrate seamlessly with the automated welding systems offered by our partner, Pemamek—a globally renowned provider of advanced automated welding and production automation solutions for high-quality steel fabrication. This seamless integration of 3D profiling and automated welding delivers crucial optimizations to your steel manufacturing process. Pemamek and HGG collaborate closely to innovate and enhance the intersection of cutting and welding.

Featured Case Study

Thanks to the PCL we’ve increased significantly our production speed - around 4-5 times.

Vladimir Voroshilov - Vyborg Shipyard