Case Study ProCutter 600 - 900

HGG Case Study at Sealevel Construction

WATCH VIDEO

About this case

Introduction

1

Machine

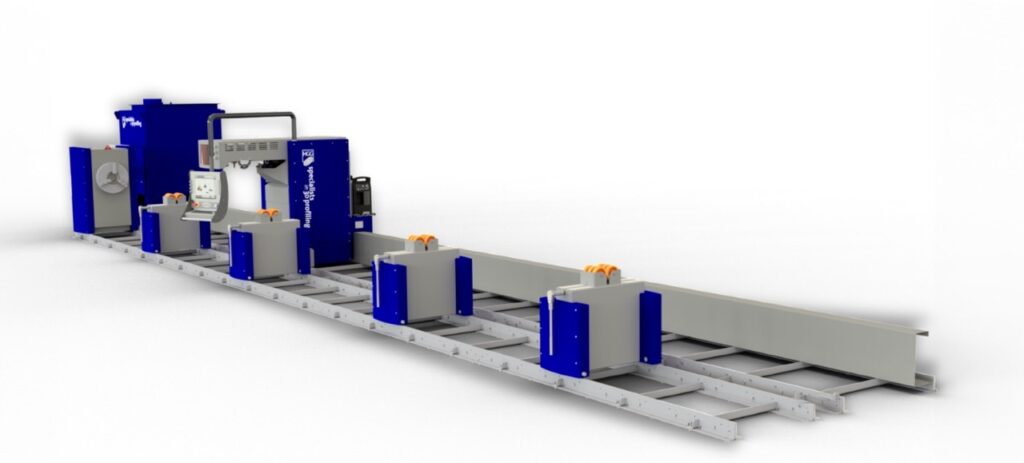

ProCutter 600 - 900

2020

Installation date

ProCutter 600 - 900

300+

Employees

Sealevel Construction inc.

1997

Established in

Sealevel Construction inc.

Meeting tight deadlines

Meeting the demanding deadlines of these projects whilst keeping the commitment and dedication that Sealevel is known for in the Southern States required a direct solution.

Brennen Cooley, Product Manager at Specks Fabrication, explained, ‘Previously, we had to lay everything out by hand and cut everything by hand. A lot of jobs would say that they needed the jobs done in 4 weeks’ time, before we would be struggling to be able to meet those lead-times. Now it’s as easy as uploading a 3D model to the machine and it’s popping it out.’

The ProCutter 600 – A Game-Changer

Finding the right machine for the job turned to be a learning experience. Tyler stated, ‘We began with a smaller unit pipe profiler and quickly realized that to sustain our growth, we needed a more robust and technologically advanced solution. Something that could work accurately and quickly and produce quality product.’

The ProCutter proved to be the perfect fit, offering the next level of automation using 3D technology, including HGG’s ProCAM software, while remaining affordable and easy to train personnel on.