HGG Case Study | Mostostal Pomorze

Precision and Flexibility

WATCH VIDEO

About this case

Introduction

Mostostal Pomorze, specializes in complex steel structures focusing mainly on offshore structures, but also including infrastructure projects and refinery installations. This mix in projects required an automated cutting solution that could easily switch between tubular and RHS structures.

Szymon Szubzda, Production Director at Mostostal Pomorze, on the impact of the MPC 450 | 500 – 1200 on their operations: “The solution we received from HGG gives us increased possibilities, because we can also cut rectangular profiles, which was a ‘must-have’ for us. We don’t always have demand just for tubular structures—sometimes there are RHS structures, and the HGG machine works effectively in both cases.”

1999

Established

Mostostal Pomorze

2024

Installation date

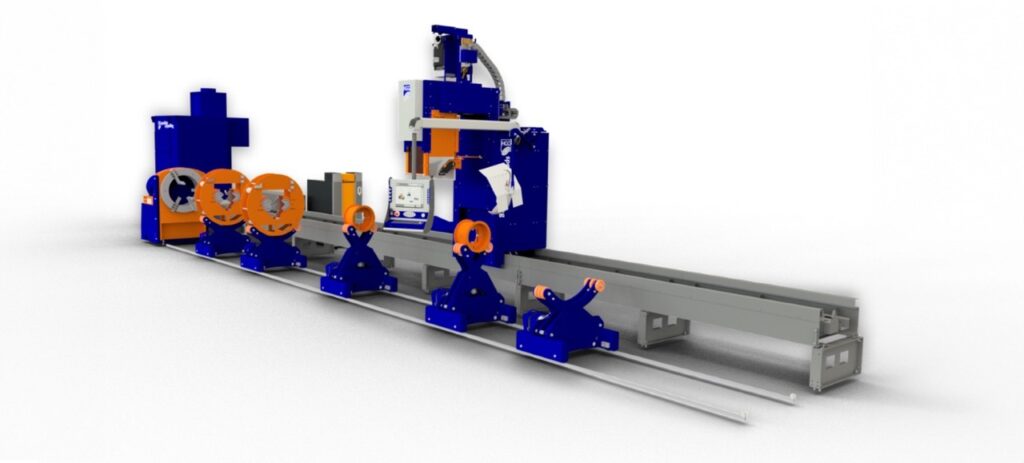

MPC 450 | 500 - 1200

A Game-Changer in Steel Cutting

Before adopting the MPC 450, Mostostal faced challenges in sourcing skilled labor and maintaining efficiency. According to Tomasz Luba, Steel Construction Division Manager, “We live in difficult times where it is hard to obtain qualified personnel. That’s why we decided to introduce automation by purchasing the HGG machine.” The investment not only helped with direct labor shortages but also significantly improved the quality and precision of their cuts reducing rework.

The MPC 450’s seamless integration into Mostostal’s production line has led to notable efficiency gains. As Krzysztof Chylinski, Technologist, explains: “For the past three years, we have started cutting many more round profiles than before in response to changing client requirements.” This transition to automated cutting has drastically reduced manual work, allowing for more precise fits and improved weld quality.

Efficiency and Future Expansion

“From the stage of ordering the machine, we were in constant and very good contact with HGG. They provided all necessary information to prepare properly for the assembly of the machine,” says Luba. Following installation, the Mostostal team received thorough training in maintenance, calibration, and operation, ensuring a smooth transition.

With the MPC 450 now fully operational, Mostostal is ready for future growth. Piotr Iwanowski, Materials and Cutting Coordinator, emphasizes the potential: “After installing the machine, we will now be able to implement larger projects and provide more services.”

“Before we bought the MPC 450 | 500 – 1200 some jobs were impossible to do at all. Now we can make very precise fits, which significantly reduces manual work.”

Tomasz Luba, Steel Construction division manager, at Mostostal Pomorze SA