About this case

introduction

The Brazilian company Ecovix– Engevix Construções Oceãnicas – provides engineering consulting and construction management in the areas of infrastructure, shipbuilding and offshore industry.

The range of diameters that Ecovix processes is very wide and varies from 20 mm (3/4”) to 760 mm (30”) with wall-thicknesses varying from 6 to 30 mm. Flexibility was, therefore, an important aspect.

10

Times faster cutting

SPC 500 - 1200 PT

6–25 mm

Thick pipes cut with ease

SPC 500 - 1200 PT

3

HGG machines

Ecovix

2010

Established in

Ecovix

Faster cutting time

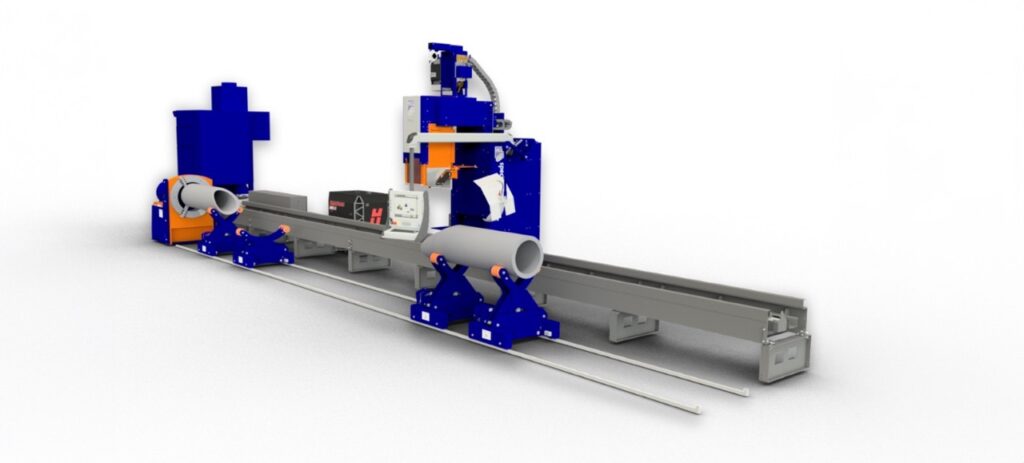

To start with a solid foundation of quality and production capacity, Ecovix bought three of HGG’s SPC pipe profiling machines only a couple of months after their establishment in 2010.

The flexibility of the SPC 800 pipe cutting machine seamlessly fit the company demands.Equipped with Kjellberg plasma cutting equipment, the SPC 800 enables Ecovix to cut 6–25 mm thick pipes very quickly. With the standard oxy-fuel cutting process, Ecovix is still able to occasionally cut thicker walled pipes

Ecovix produces lots of spools. Once cut on one of the HGG SPC 800 pipe profiling machines, the parts are ready for further processing. ‘Grinding is no longer needed and our cutting is almost ten times faster.’ Wagemaker adds

Ecovix looks to the future

This investment in automation enabled Ecovix to successfully face future challenges and bigger projects. In the future Ecovix will be looking towards more extensions and upgrades of its existing SPC 800 pipe profiling machines. The latest machine in the workshop is HGG’s PCL 600 Profile Cutting Line, which will drastically improve the production of shipbuilding activities.

‘In order to improve our production capacity and offer high quality products, we knew we had to invest in high-end and innovative machines to use in our pipe shop’

Ricardo Wagemaker, Pipe Shop Manager at Ecovix