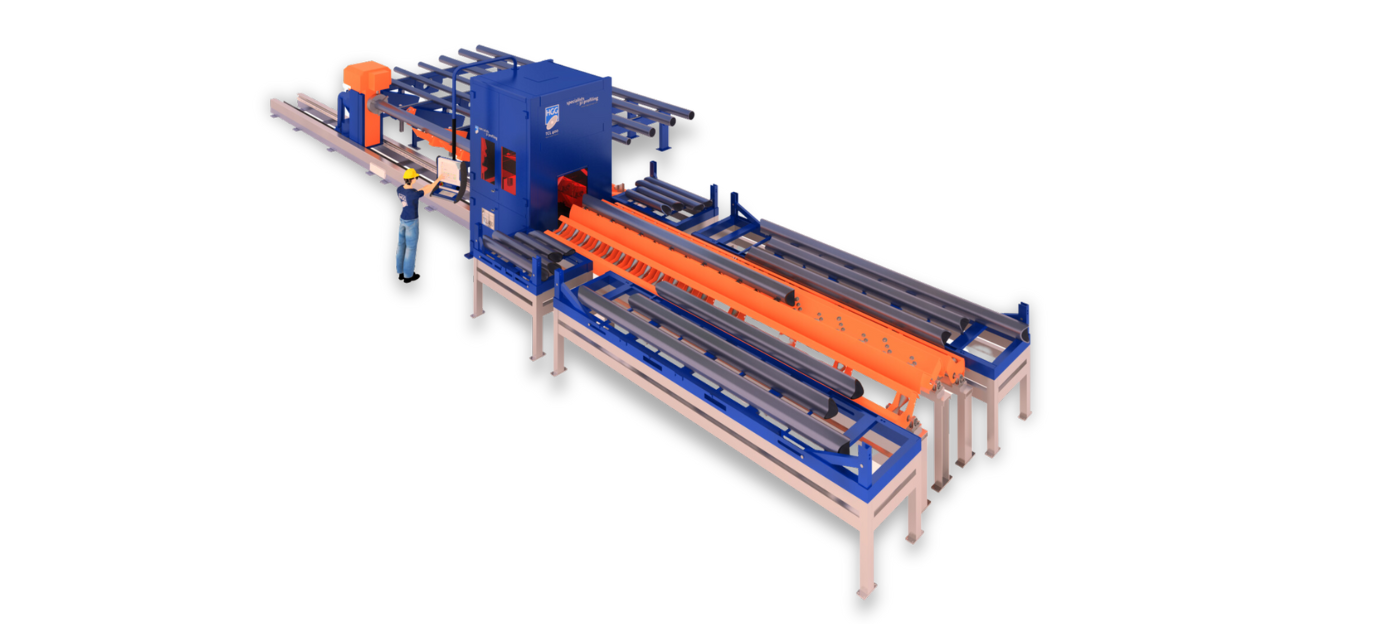

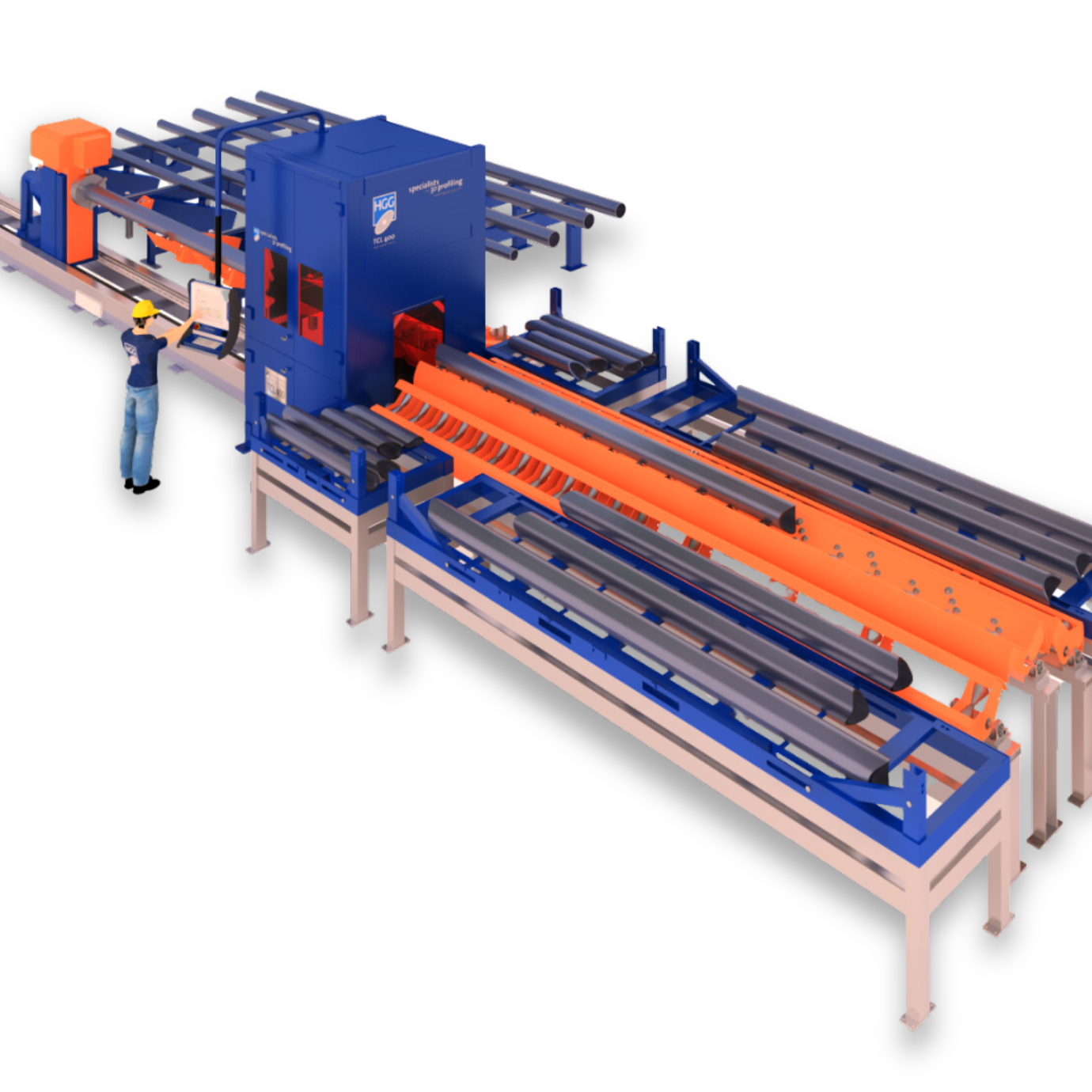

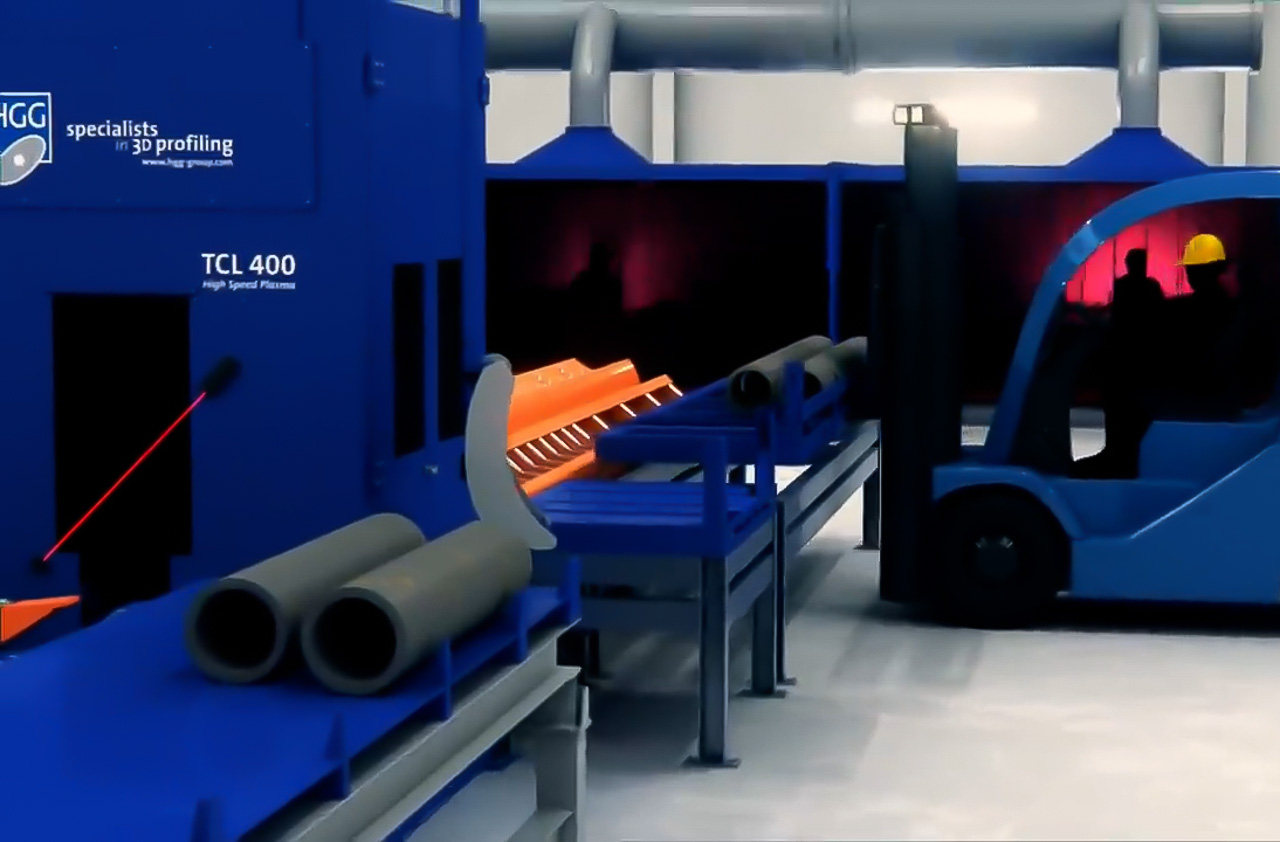

Product Animation TCL 400

The Next Generation of Pipe Cutting

WATCH VIDEO

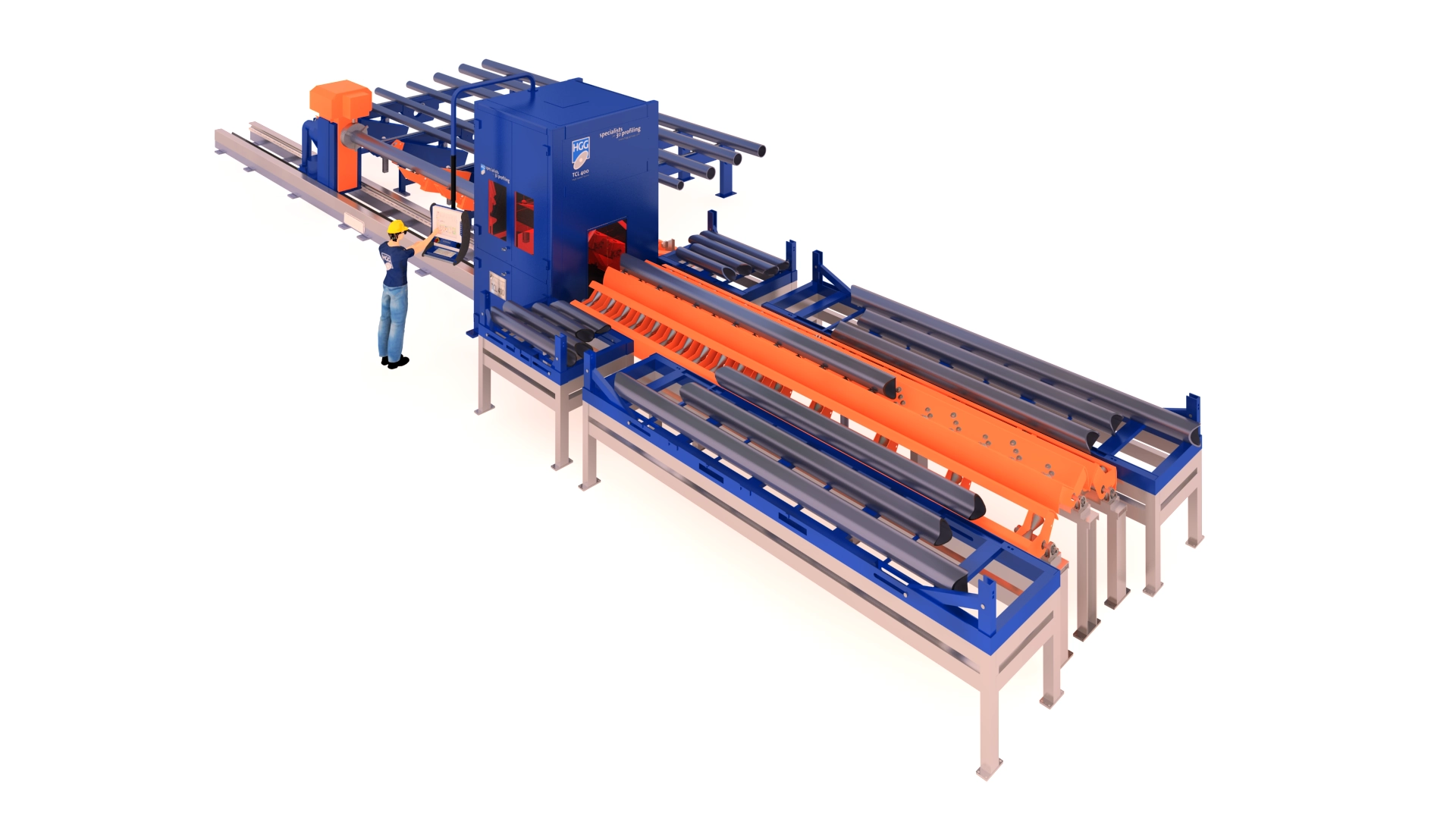

From stock pipes to ready-to-fit parts

The TCL 400 optimizes the product flow and automates your workshop increasing your throughput. Simply load your material onto the infeed table and pick them up from the output after processing. No more rework needed. Create a seamless workflow from raw material to finished components.

Specifications

Profile & Dimensions

- Profile

- Minimum

- Maximum

| 48 mm | 406 mm |

| 2 “ | 16 “ |

Additional Specifications

- Plasma cutting

- Plasma marking with cutting torch

- Powersource: Hypertherm or Kjellberg

Discover the possibilities of the TCL 400

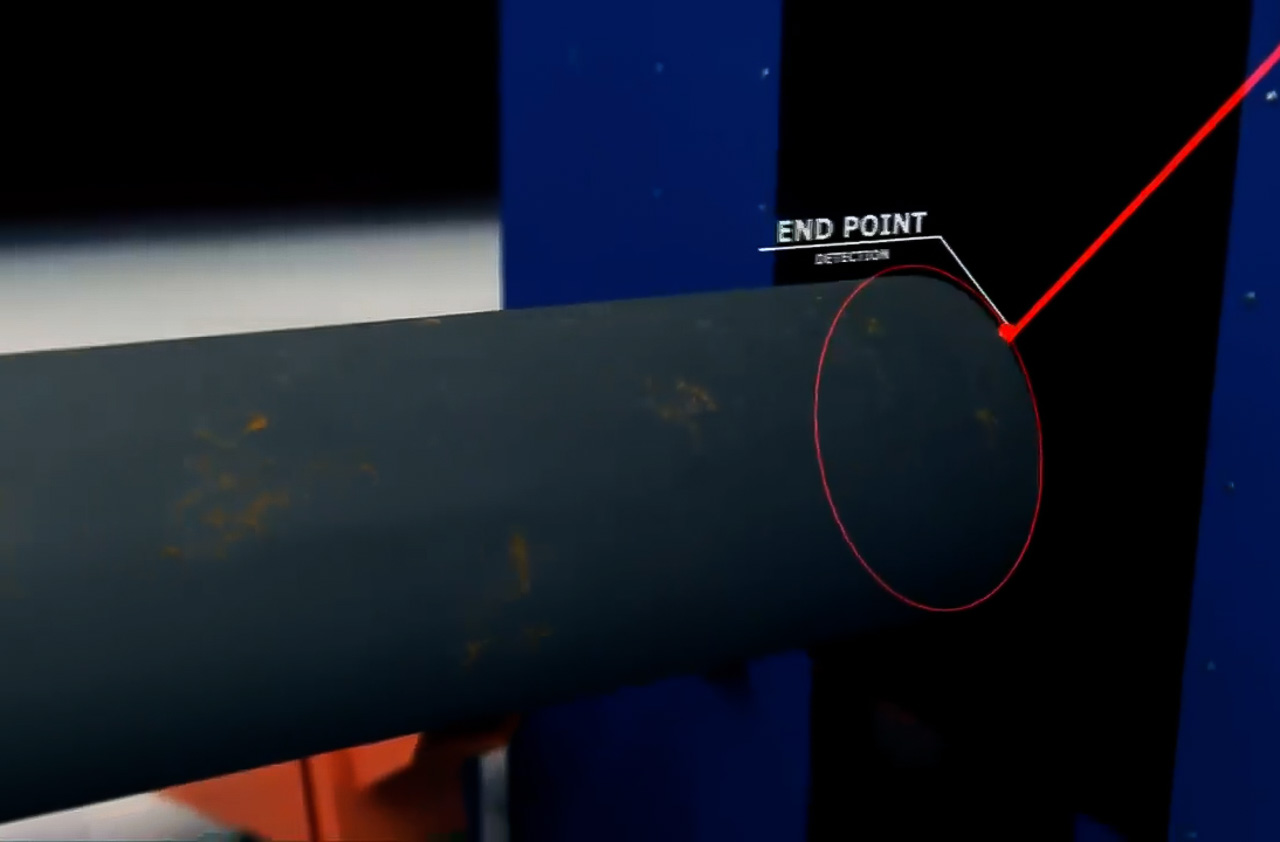

Cut with Plasma

HGG has distinguished itself as a pioneer in CNC plasma cutting. Since 1994, HGG has supplied over 500 3D profiling machines with plasma cutting technology worldwide and keeps innovating with plasma cutting technology to stay on top of the latest developments.

HGG offers unique features that further improve the quality of plasma cutting by compensating for plasma characteristics and/or prolonging consumable lifetime.

We support both Kjellberg and Hypertherm plasma sources. Two well experienced and industry leading choices.

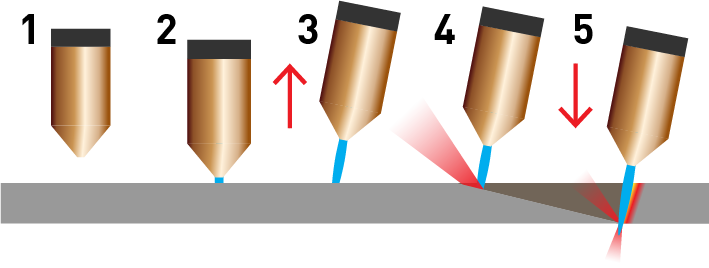

With Angled Piercing technology to protect your plasma consumables

Plasma consumables can become costly if you need to replace them regularly. The angled piercing routine keeps the nozzle and other consumables out of harm’s way, saving you time and money.

Related Case Studies

Shipbuilding

Client

Civmec

Industry

Shipbuilding

Machine

SPC 1500 - 3000 PT & RPC 1200 Mk3

Process Piping

Client

Enerflex Ltd

Industry

Process Piping

Machine

SPC 1500 - 3000 VC

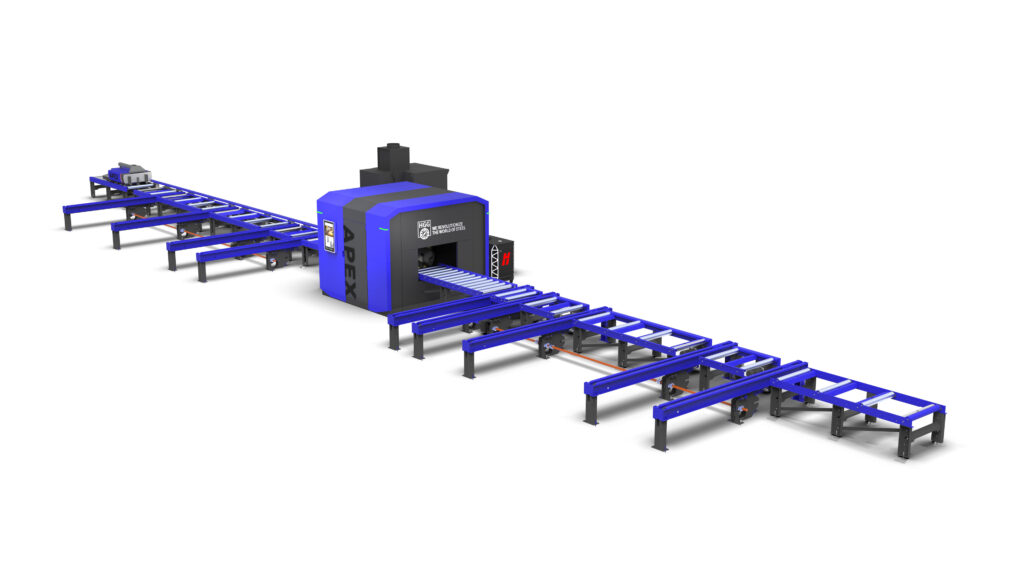

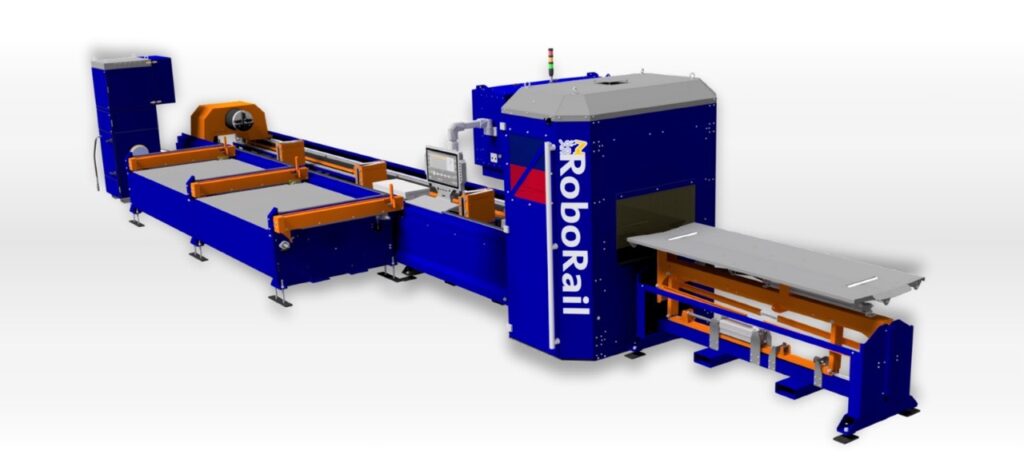

Related Machines

With over 40 years of 3D profiling experience, we provide the industry’s best 3D profiling machines. Our machines are fully compatible with our in-house-built ProCAM software, ensuring seamless integration from CAD data to CNC cutting files.

Industry

Offshore, Steel construction

Process

Industry

Steel construction

Process

Industry

Steel construction