How to trim cuts when profiling a vessel head?

When you are a pressure vessel manufacturer, you know all about the challenges when it comes to profiling your vessel heads or tank heads. Regularly most of the required profiling stays within the 80% of the diameter zone. But what to do when you need to profile shapes or holes outside this zone?

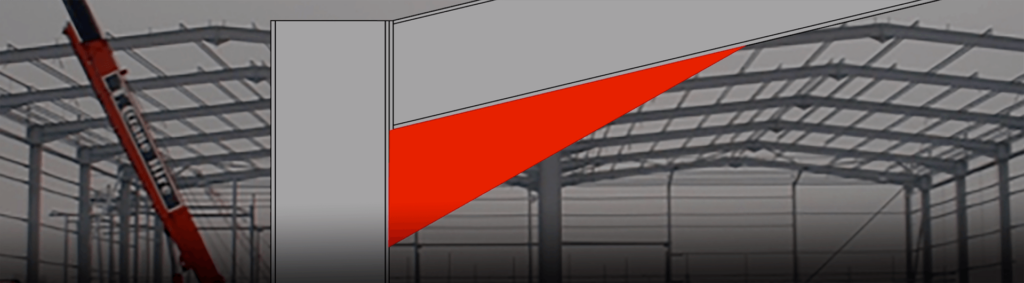

How we optimize automated haunch cutting

Cutting haunches is crucial when you’re fabricating portal frames, like hangars or factory halls. Cutting them manually is a very time-consuming process. Learn how to save time with automated haunch cutting.

Maximize your quality output with PerfectHole Technology

HGG’s PerfectHole technology ensures a perfect bolt hole by utilizing the multiple axes from the cutting trolley and cutting head.

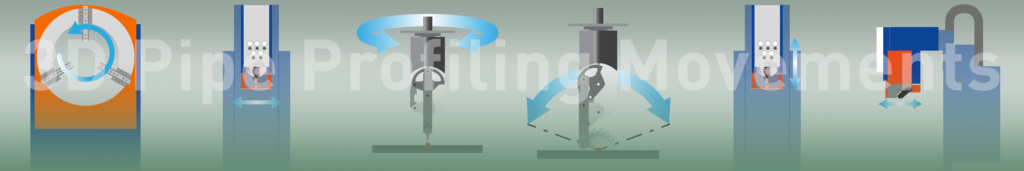

5 Movements to create the perfect cut every time

Our machines utilize 5 points of movement to create the perfect cut everytime. We will quickly go over the basics on how Complex 3D profiling is achieved with a pipe profiling machine.

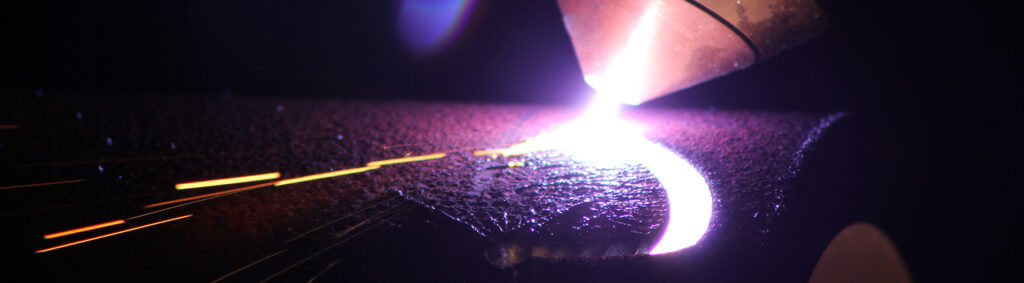

5 factors that influence optimal plasma cuts

A precision cut is key to a good end-result. Let us explain 5 factors that you can influence to make the optimal plasma cut.

Cut angled pipe to pipe connections faster with PJP

Save valuable cutting time with the Partial Joint Penetration (PJP). A pipe to pipe connecting cut optimized for plasma and speed.

Laser Pipe Cutting Versus Plasma Pipe Cutting

In this article, we will explore the advantages of laser cutting in general, as well as with respect to pipe. And we will explain when plasma cutting is your best option.

Invest in Automation to Improve Production Efficiency

The case study in this article details the story of Kurganstalmost, a Russian market leader in metal superstructures. Kurganstalmost realized significant productivity gains after investing in automation by purchasing cutting equipment.