Distorted pipes, with large seam welds, a bow shape or an uneven ovality across their length benefit from less movement. Especially intermediate cuts can be negatively influenced. HGG’s PerfectHoleTM Technology, where holes are cut with guaranteed accuracy, is useful in certain cutting situations.

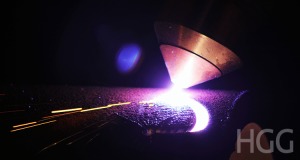

Utilizing multiple CNC axes

By utilizing the multiple axes of the cutting trolley and cutting head, hole cutting requires no rotation of the pipe. This eliminates the possible changes in direction from the weld seam or the ovality of a pipe with inaccuracy as result.

These potential issues are solved by PerfectHole cutting, which is advised to those who want to maximize their quality output.