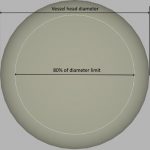

The 80% of diameter zone

HGG’s pipe and vessel cutting machine SPC 1500 – 3000 VC is very well capable of profiling shapes and holes on vessel heads or tank heads to the limit of 80% of the vessel head diameter (see image below) to guarantee quality and reduce rework. And even cuts required outside this zone can now be processed on the machine.

Holes outside the limit

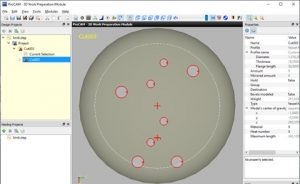

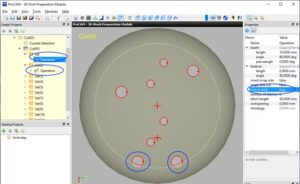

Sometimes data files contain cuts that are partially located outside the 80% diameter limit. Usually, when a part of the cut is located outside of this limit, the entire cut needs to be excluded from profiling, with time-consuming process of laying out by hand as a result. In order to improve the processing speed of the entire vessel in a situation where one or more cuts are partially located outside this 80% diameter limit, HGG developed a new ProCAM functionality. This new ProCAM functionality is created to trim holes which are partially located outside the 80% diameter limit. Let’s look at an example below.

The two holes at the bottom are slightly outside the 80% diameter limit. An error will appear in the log window and on the part in the design explorer. At this point, a user is not able to create cutting files, or select ‘Start profiling on machine’. The error could only be resolved by setting the ‘Cut’ property to ‘false’ for both holes.

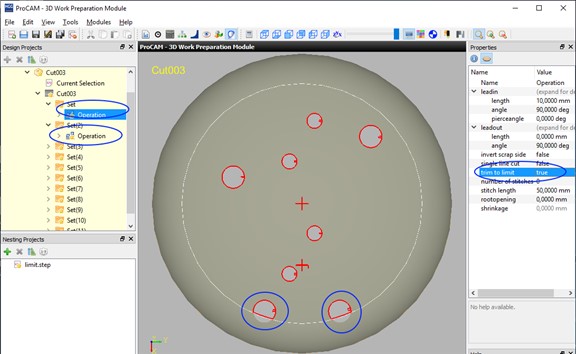

Trim to limit

The new ‘trim to limit’ functionality can trim the cuts to fit within the 80% diameter limit and is directly visible in the 3D Work Preparation Module. Activating the ‘trim to limit’ will remove the error icon from the design explorer and both options to create cutting files and start profiling on the machine are available again. ‘Trim to limit’ can be set to ‘true’ for a single cut independently, for every part, to make all hole cuts that cross the 80% diameter limit trimmed, or enabled for every vessel head in ProCAM settings. Enable these features with the following step:

1. Single cut

In the properties window on the right side of ProCAM change the drop-down behind ‘trim to limit’ from ‘false’ to ‘true’.

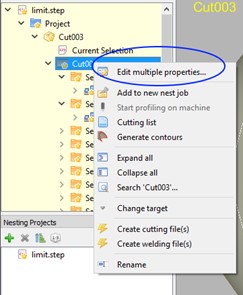

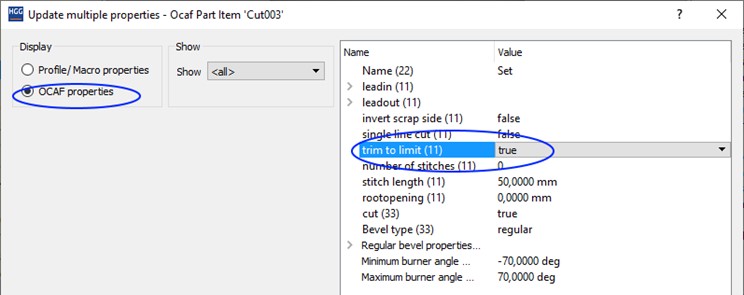

2. Single part

Right click the ‘Part item’ in the design explorer and click on multiple properties. Next, select OCAF properties and change the drop-down after trim to limit from false to true.

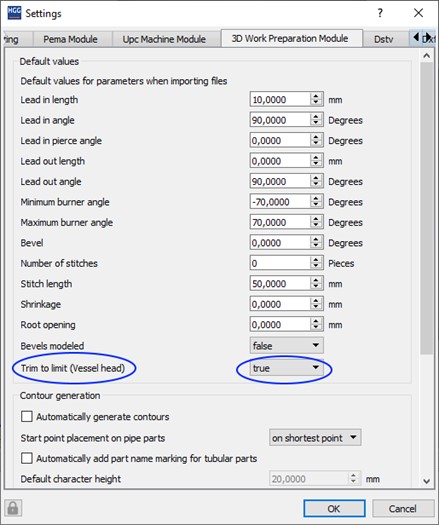

3. Every imported vessel head

Change the default behavior of the property in the ProCAM settings. Go to ‘Edit’-> ’Settings’ -> ‘3D Work Preparation’. Under ‘default values’, set ‘Trim to limit (Vessel Head)’ to true.

Are you interested in this functionality?

Do you use an HGG SPC-VHC to cut your vessel heads or tank heads and are you interested in this new functionality? Contact us!