About this case

Introduction

Based in vibrant Singapore, Techniques Air Conditioning & Engineering Pte Ltd, is a leading expert in heating, ventilation, and air-conditioning engineering. Whilst the world was dealing with the challenges of the COVID-19 pandemic in 2020, Techniques Air decided to take their company philosophy of optimizing labor utilization and productivity, to the next level, opting for not one but four HGG 3D Profiling Machines

At techniques Air’s state-of-the-art 90,000 square-foot pre-fabrication facility, which boasts multiple smart production solutions, they cater to clients across diverse industries such as biomedical research, semiconductors, microelectronics, and data centers. Over the years, they have built an impressive track record in constructing critical systems such as clean rooms, gases and chemical piping, and engineered smoke control systems

4

HGG Machines

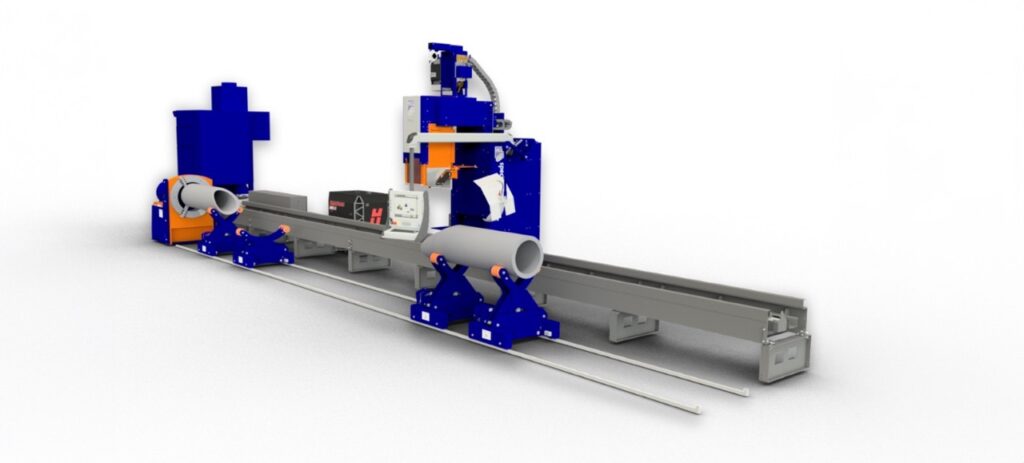

SPC 500 - 1200 PT

2022

Installation date

SPC 500 - 1200 PT

173

Total projects

Techniques Air Conditioning & Engineering Pte Ltd

1983

Established in

Techniques Air Conditioning & Engineering Pte Ltd

Local support from the HGG Asia Team

Combining precision profiling with automated welding

As COVID restrictions eased in the last quarter of 2022, a commission engineer from HGG’s Headquarters in the Netherlands was finally dispatched for final calibration and installation services. With all four SPC machines now fully operational, the company now boasts the most modern production facility automating craftsmanship to maximize productivity, especially in the face of labor shortages.

The commitment to innovation, productivity, and quality, coupled with the support from HGG, has propelled them to overcome the challenges posed by the pandemic and achieve remarkable success in their specialized field of air conditioning engineering. Their cutting-edge production facility, powered by HGG’s advanced profiling machines, has positioned them at the forefront of today’s industry.