Case Study SPC 500 - 1200 PT

HGG Case Study at SOLB26

WATCH VIDEO

About this case

introduction

Setta Wa Eshroon Solb W.L.L. (formerly called Nurol Gulf), established in 2007, is known for its expertise in the design, fabrication, erection and commissioning of heavy structural steel works. The company operates in a region and industry that has been booming in the last years – structural steel in the Middle East. Billions of dollars have been invested in the development of high quality infrastructure and state-of-the-art sports stadiums, e.g.: the Handball World Cup in 2015 and the FIFA World Cup in 2022.

1

Machine purchased

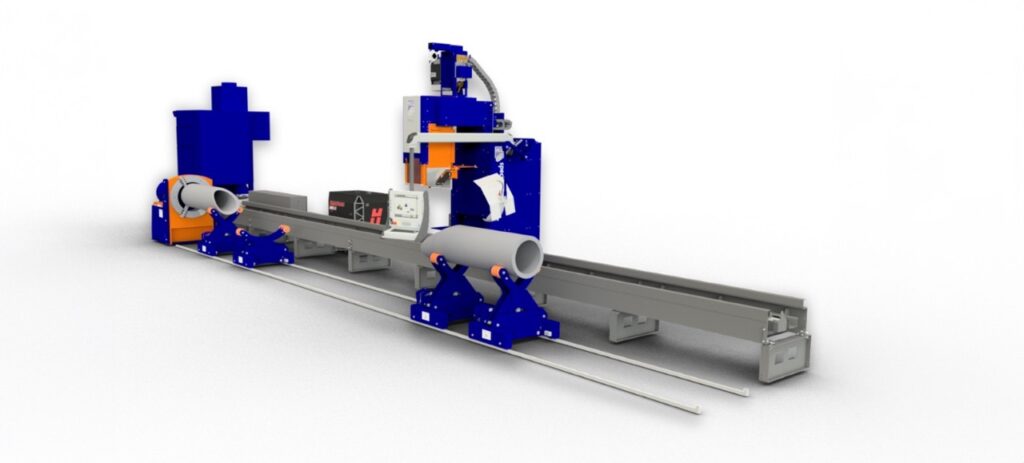

SPC 500 - 1200 PT

40

Tons of pipes cut a day

SPC 500 - 1200 PT

3.500

Tons of steel produced monthly

SOLB26

2007

Established in

SOLB26

Higher requirements

To keep up with the more stringent requirements from customers, SOLB26 was looking for ways to realize more complex structural designs, fabricate larger volumes, with better quality and in shorter time frames. Finding highly-skilled craftsmen also becoming a critical challenge for the fabricator.

Solving the issue

To solve these challenges, the company purchased the SPC 500-1200 PT, HGG’s most tried-and-trusted pipe cutting machine. The SPC 500-1200, equipped with an in-house developed software suite which allows interfacing to any design system generating NC data files, allowed SOLB26 to realize even the most complex structural design, such as the FIFA World Cup in 2022 stadium in Qatar. The quality of the cuts improved drastically, which resulted in savings on fitting and welding, which significantly increased the company’s fabrication capacity: “Before purchasing the SPC 600 pipe profiling machine we were cutting up to 10-20 tons of steel per day. Right now we are capable of cutting over 40 tons of pipes a day!“, explains Mr. Aladag.

In the design of new projects, you do not want to be restricted by lack of technical capability. When you eliminate these limitations, which the SPC 1200 does, you will be able to realize much more complicated and extraordinary designs.”

Mr. Aladag, Technical Office Chief Engineer at SOLB26