Case Study SPC 660 - 1200 RB

HGG Case Study at Exterran Corporation

WATCH VIDEO

About this case

introduction

Exterran is a full-service natural gas compression fabricator doing in-house everything from cutting the vessels to having the piece fully-assembled.

2

People doing the work of 8

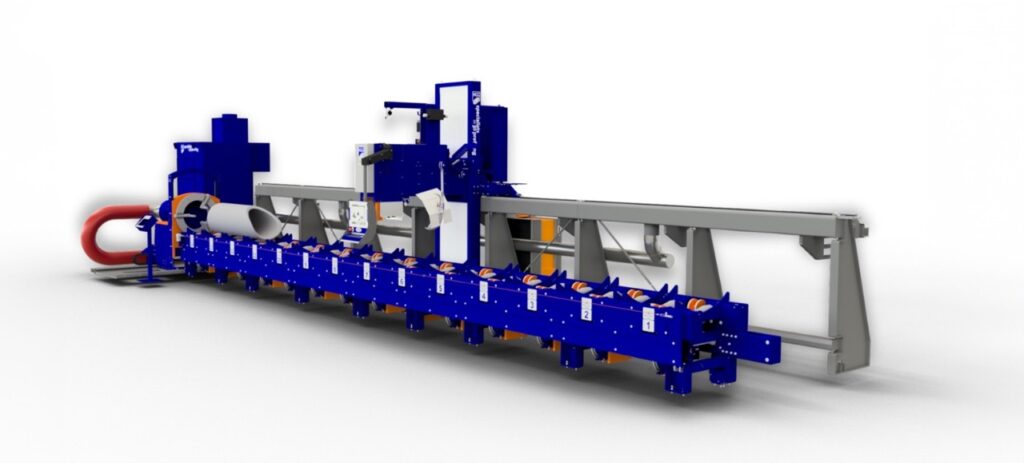

SPC 660 - 1200 RB

3

Months for full payback

SPC 660 - 1200 RB

2.800

Employees in the US

Exterran

2007

Established in

Exterran

How it used to be done

“Before acquiring the SPC 660 – 1200 RB, the process of creating shell layouts was entirely manual. It began with a basic pipe and drawings, where craftsmen meticulously laid out the design using chalk lines and manually stamped markings for precision.”

A perfect cut

The productivity gains from cutting with HGG’s SPC 1200 RB Pipe Cutting Line for Exterran were numerous. Thanks to the perfect cut results the follow-up processes were highly optimized, too. The grinders and welders are now dedicating their time to their core activities only: grinding & welding. Both processes now take less time. Man power has been allocated in a more efficient way: 2-3 people doing what used to be done by 8-10 people. “Within 3 months we should have our full pay-back on the SPC 660-1200 RB pipe cutting line.”, concludes Mr Cruz.

“When you do the cutting manually it is never accurate. You either have a really small or a really large gap at your root opening. With a larger gap there’s more room for error.”

Ricky Cruz, Value Stream Manager at Exterran