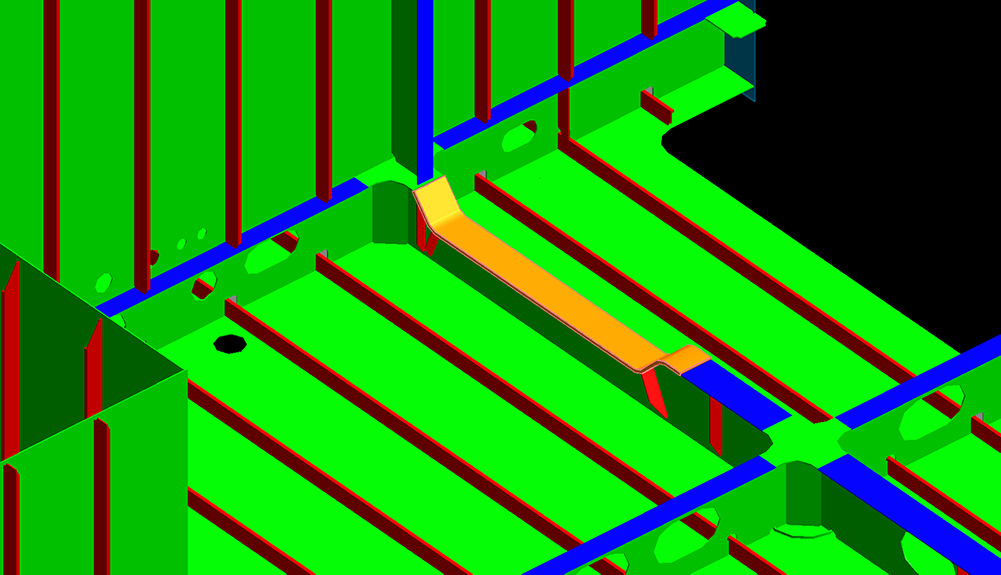

A part can contain one or more knuckles. They can be located anywhere, as long as it’s not at the beginning and end of the part. The knuckle macro marks the area where the part should be bent. It contains a text label indicating bending direction, length and radius.

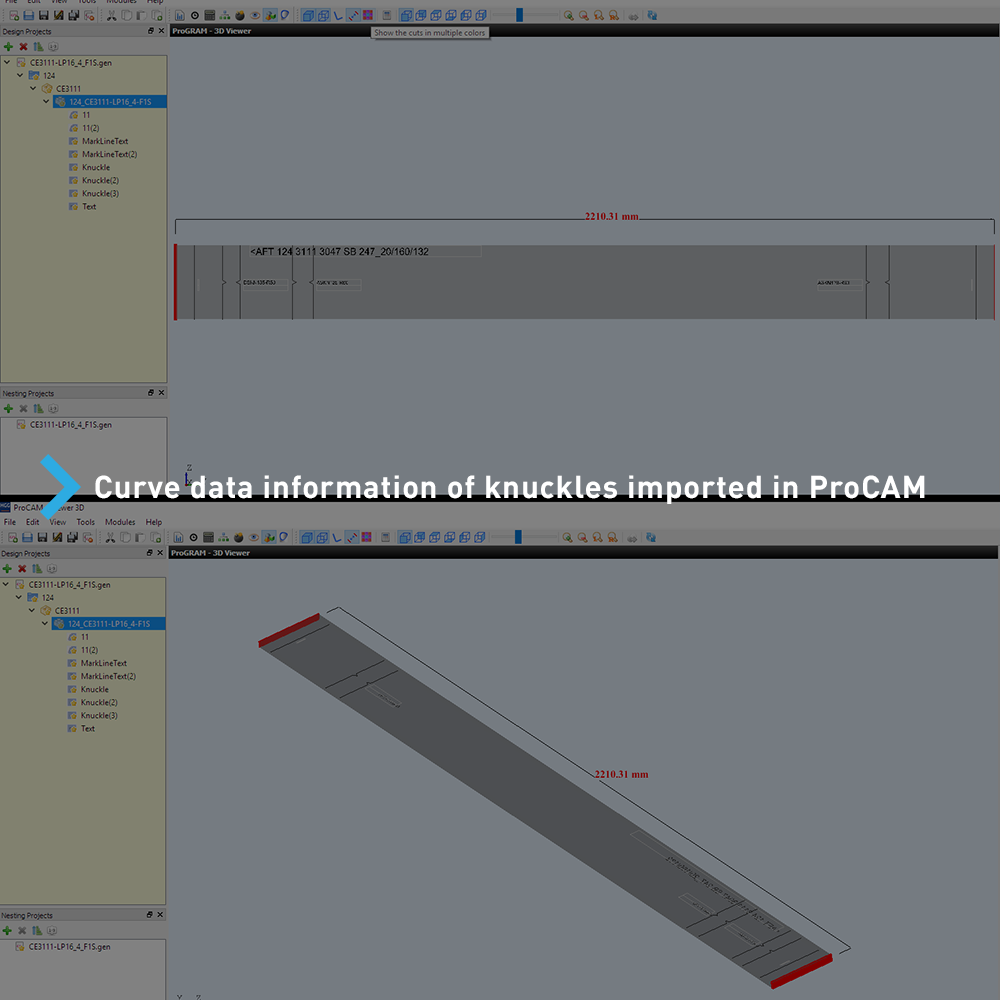

The curve data information from CAD is imported to ProCAM where users are able to verify the knuckle and edit text additionally.

Available on all PCL 600’s

The knuckle macro saves time and manual labor, while it also reduces errors. The knuckle marking macro is specially developed for all new PCL 600 machines. It’s added to the standard package of PCL macros.