Case Study ProCutter 600 - 900

HGG Case Study at Victor A/S

WATCH VIDEO

About this case

Introduction

Victor A/S is a Danish Steel Construction company specialized in refrigeration, piping & process, subsea & structures and screw conveyors for the offshore, marine & energy industries. With their increasing order volume Victor A/S were no longer capable of processing accurately the wide variety of pipe lengths, diameters and wall thicknesses for all those industry applications with their sawing and beveling machines. Cutting and grinding was taking very long and high quality was difficult to achieve.

1

Machine

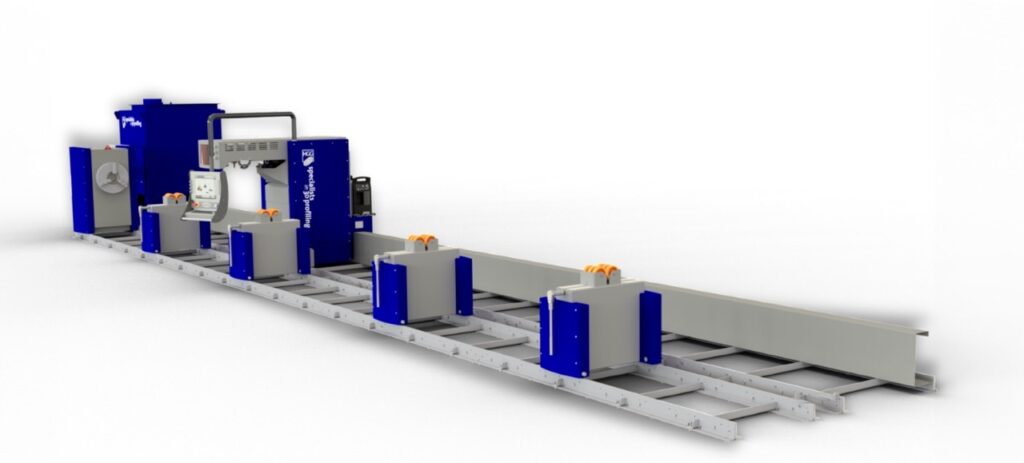

ProCutter 600 - 900

2012

Installation date

ProCutter 600 - 900

30%

Time saving on welding and fitting

Victor A/S

2000

Established in

Victor A/S

Automated solution

On a certain moment Victor A/S realized they need an automated solution for the various pipe related projects, both for fluid handling and for steel construction projects. To make better use of their manpower and fabrication facility space they were looking for one single automated cutting line for all the pipe cutting and beveling work.

Victor A/S purchased the HGG ProCutter 600, our 3D Profiling Machine equipped with both oxy-fuel and plasma, covering a wide variety of materials, sizes and wall thicknesses. HGG’s ProCutter 600 CNC Pipe Cutter proved to fit the needs of Victor A/S perfectly: ‘We use the machine for various pipe related projects, both for fluids handling and for construction.

Faster processing

“Both handrails and pressure vessels can be cut,” claims Mr. Nygaard. “With the ProCutter 600, Victor A/S can now process faster and very accurately, along with realizing savings on fitting and welding.”

“The PC 600 saves us over 30% on fitting and welding; previously we needed 4 hours for grinding and making the holes on 10 pieces. With the ProCutter 600, we can do the same thing in ½ hour. The HGG pipe cutting machine makes the welding job a lot easier. After cutting the parts, they just fit together very nicely!” Mr. Ole Nygaard adds.

‘We process so many different kinds of pipes. Not only 2–3 inch pipes, but also bigger pipes of 12–14 inches, so we needed a reliable solution for cutting accurately all dimensions within this pipe range.’

Mr. Ole Nygaard – Managing Director at Victor A/S