Case Study ProCutter 600 - 900

HGG Case Study at Grupo Carso

WATCH VIDEO

About this case

introduction

In the northeast of Mexico City rises the new international airport of Mexico, also known as Nuevo Aeropuerto Internacional de la Ciudad de Mexico (NAICM). The unique and spectacularly designed X-shaped airport contains various ‘fonils’, which are almost impossible to cut manually.

HGG supplied Carso with the ProCutter 600 pipe cutting machines and the software that dramatically increased its production.

To realize this complex structure in a traditional way, which would be manual, is almost impossible’, Christian Hernández, manufacturing engineer says.

3

Machines delivered

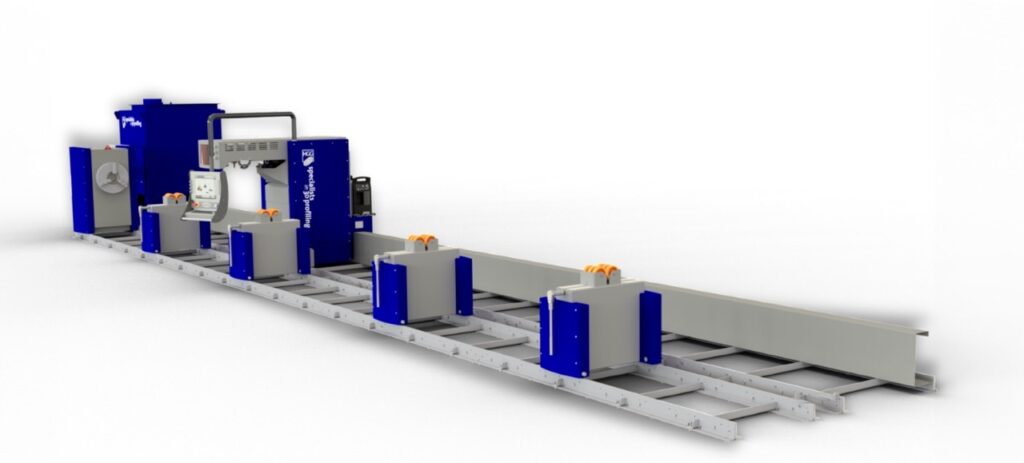

ProCutter 600 - 900

2014

Machine installed

ProCutter 600 - 900

7000

Pipes per structure

Grupo Carso

72.000+

Employees

Grupo Carso

Fabrication glory: From one entire week to only one day

While Carso had the know-how and the tools for commercial and industrial projects, the sheer magnitude of the NAICM project made it look for help. Through IP Grupo, a dealer in steel processing machinery, Carso got in touch with HGG and struck a deal for the delivery of 3 pipe profiling machines. As General Manager Saul summarizes: “Without this kind of machinery it wouldn’t be possible to produce these structures in the required time and quality.”

‘Since we have this machine, production increased greatly’

The influence of HGG’s machinery trickles down to all departments. Thanks to the machines’ seemless integration with the software package Tekla Structures, designs are quickly passed on to the cutting shop. “Before, we had to take a lot of steps, even with automated machinery. What HGG does with Tekla really pleases me,” says manufacturing engineer Christian Hernández. “The human error factor is reduced and the production volumes have grown immensely.”

Industrial engineer Sofía Morales agrees: “We can take this fonil from the design stage to the cutting stage within one day. This is something that used to take us one week.”

'Without this kind of machinery it wouldn't be possible to produce these complex structures in the required time and quality'.

Saul Higareda – General Manager Carso