There’s often much confusion in welding terms. In this article we explain some of the most used welding terms.

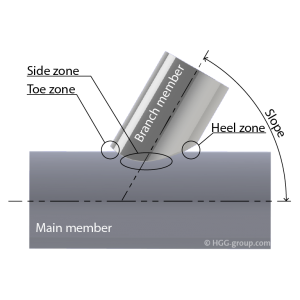

Branch member

Sprouted profile, mostly with an ‘end’ profiling shape (or none).

Main member

Stem profile, mostly with an ‘intermediate’ profiling shape (or none). Also called ‘run member’.

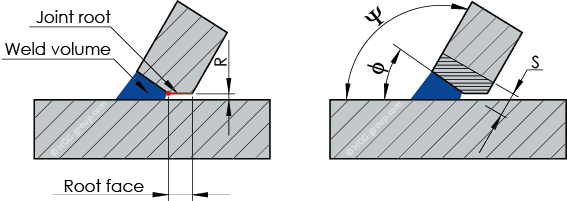

Joint root

That portion of a walls end along the joint where the members approach closest to each other. In cross section, the joint root may be either a point (fit line) or a line (root face).

Root face

The cut face on a walls end along the joint root, parallel to the other connecting face after fitting. A technique to decrease weld volume and/or to create a mold for perfect fitting.

Root opening (R)

The separation at the joint root between the members after fitting. Technique to increase the joint penetration for stronger connections.

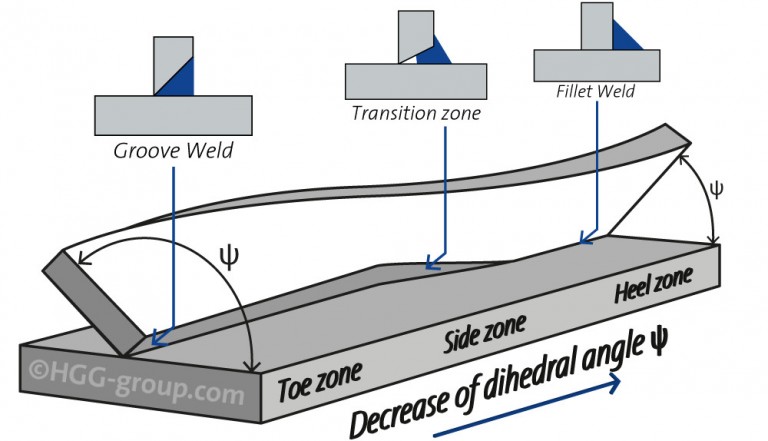

Transition zone

Zone in which one of the two welded faces of a connection will smoothly changes to fit to another face, to ensure an optimal weld preparation. In particular when the dihedral angle becomes too small or too large along the joint root.

Shrinkage (S)

A length compensation of the member to correct shrinkage of the weld.

Slope

Angle between main member and branch member.

Dihedral angle ψ

Angle between the connected outer faces of the members along the fit line. Essential to make calculations for optimal weld preparation.

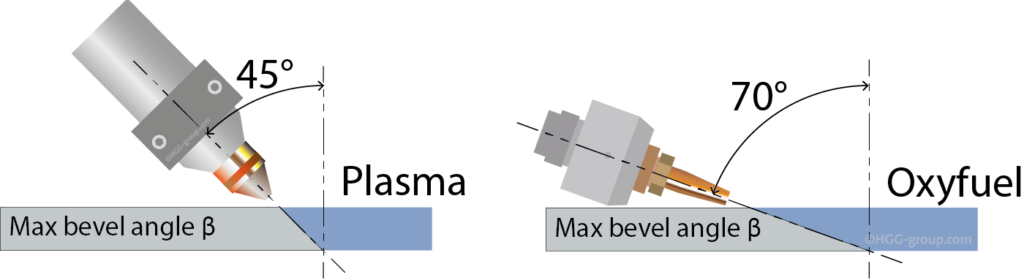

Bevel angle β

The angle formed between a centre line perpendicular to the wall and the cut face of the wall. Equal to burn angle and can be negative or positive.

- A perpendicular cut has no bevel;

- Largest bevel oxy-fuel 70° (- or +);

- Largest bevel plasma 45° (- or +).

Weld preparation angle φ

Angle between the to be welded faces of the members along the joint. Can be an inside or outside weld preparation angle. Also called ‘Joint included angle’. A groove angle for example, is a type of weld preparation.

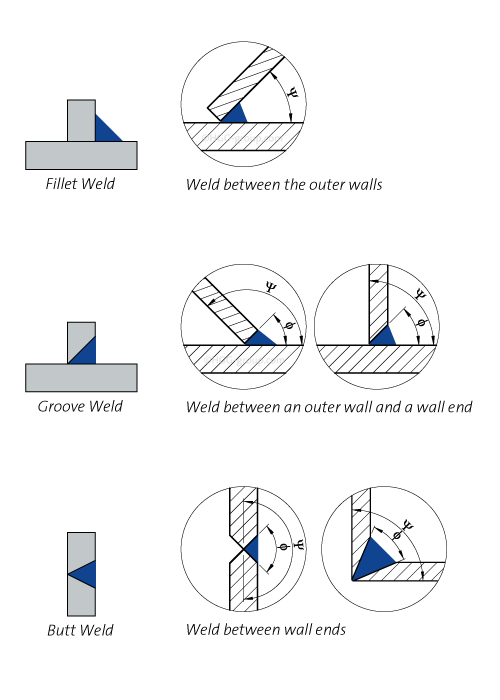

Fillet weld, groove weld and butt weld

The angle between the member walls along the joint root changes constantly (see picture below for a simplified view). This dihedral angle is greatest in the toe zone and smallest in the heel zone. On some joints, this dihedral angle differs considerably. In order to maintain a strong connection along the joint in these situations with a minimum of weld volume, it may be necessary to use a combination of weld types.

For example, a fillet weld in the heel zone because of the small dihedral angle and a groove weld in the toe zone because of the large dihedral angle. Somewhere between these weld types along the joint root, is a zone where the transition starts and ends. This zone is called the ‘transition zone’.