By automating the cutting process and applying smart weld preparation techniques the materials are ready for fast and easy fitting and welding. This can save you up to 30% on in-site labor costs and weld volume. Saving welding volume is done in 3 ways.

Firstly a smooth cut surface as they say ‘all humps are extra welding volume all bumbs need grinding time’. Secondly compensate cutting shape for exentricity and slope so that the groove angle is constant. Lastly strategic reduction of the groove angle in some cases when a connection is sloped the toe zone allows for a volume reduction.

The 7 most used profiling shapes for process industry explained

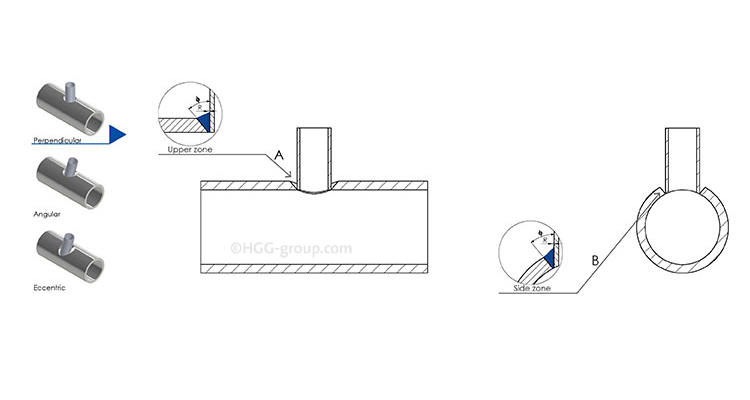

Saddle set-in & Hole set-in

For pressure connections with a much smaller branch member diameter.

Design Freedom

- Adjustable slope.

- Adjustable eccentricity (E).

Weld Preparation

- Adjustable root opening (R).

- Adjustable constant weld preparation angle (φ) along the joint root.

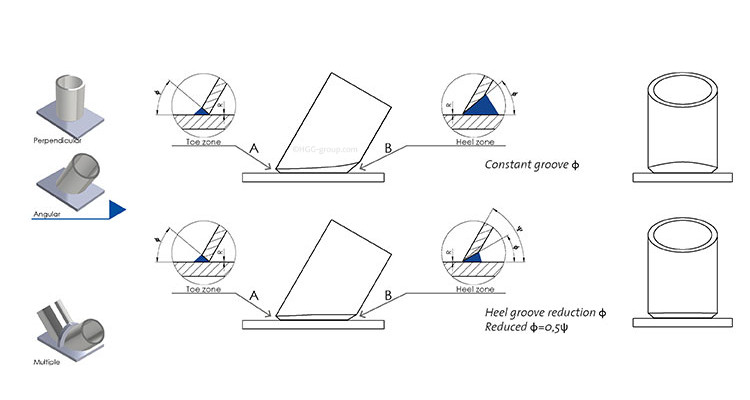

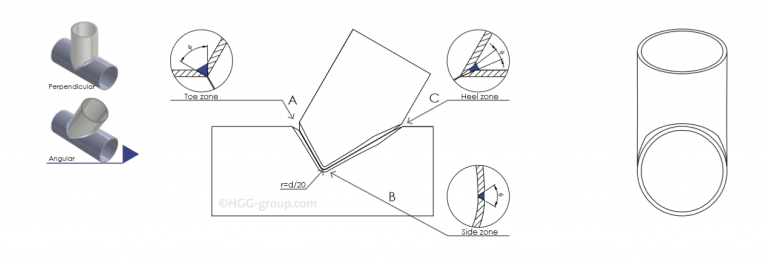

Chamfer

A chamfer is a pipe to plate connection.

Design Freedom

- Adjustable slope.

Weld Preparation

- Shrinkage compensation,

- Adjustable root opening (R),

- Adjustable constant weld preparation angle (φ) along the joint root,

- Heel groove (φ) reduction available to reduce weld volume.

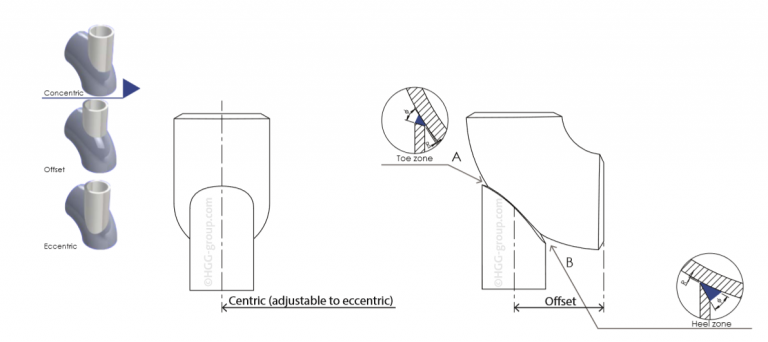

Elbow Saddle

Elbow support against gravity for piping industry.

Design Freedom

- Adjustable Slope,

- Adjustable eccentricity (E),

- Adjustable centre line offset.

Weld Preparation

- Shrinkage compensation,

- Adjustable root opening (R),

- Constant weld preparation angle (φ) (groove) along the joint root.

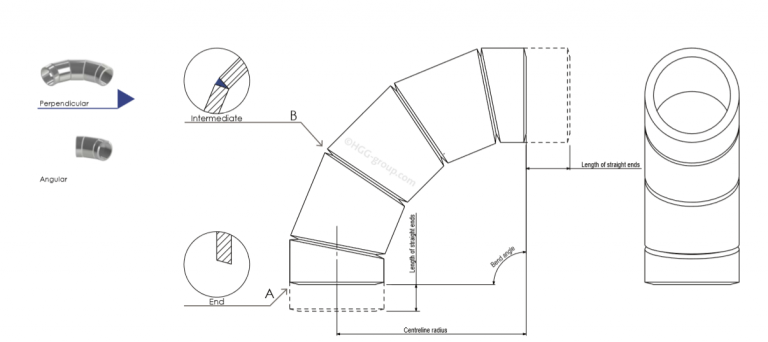

Lobster Back

Tool to create series of closely spaced mitre bends.

Design Freedom

- Adjustable angle of total bend.

- Adjustable centre line radius.

- Adjustable amount of segments.

- Adjustable length of straight ends on both sides.

Weld Preparation

- Adjustable end bevel.

- Adjustable intermediate weld preparation angle.

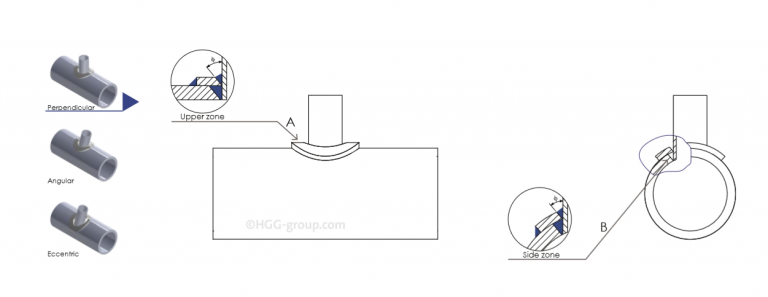

Mitre

To make T-shaped pipe to pipe connections for low pressure piping.

Design Freedom

- Adjustable slope.

Weld Preparation

- Mitre Saddle: shrinkage compensation.

- Adjustable root opening.

- Constant weld preparation angle (φ) along joint root as long as the maximum bevel angle is not reached.

Reinforcement Pad

To save material costs by reinforcement of the weakest point on ‘Saddle-Hole’ connections.

Design Freedom

- Adjustable slope.

- Adjustable eccentricity (E).

Weld Preparation

- Add a ‘Saddle Set-in’ and a ‘Hole Set-in’ for maximum reinforcement.

- Hole; adjustable constant weld preparation angle (φ).

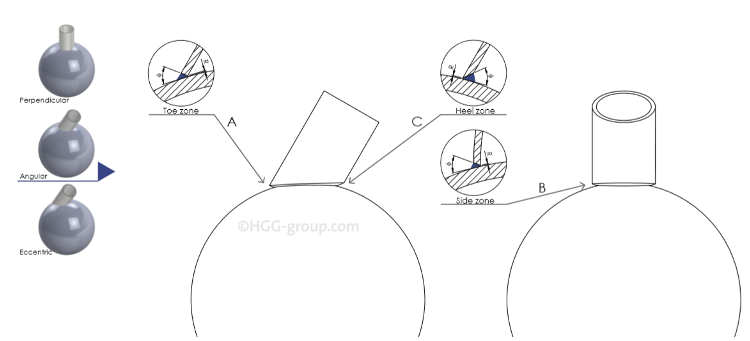

Sphere Saddle

To connect a pipe to a ball shape.

Design Freedom

- Adjustable Slope.

- Adjustable eccentricity (E).

Weld Preparation

- Shrinkage compensation.

- Adjustable root opening (R).

- Adjustable constant weld preparation angle (φ) (groove) along the joint root.

More profiling shapes for the process industry?

This is only a selection of a few possible profiling shapes for the process industry. Do you want to know more about other possible profiling shapes for the process industry? Contact our 3D Profiling Specialists for more information.