Why limit yourself when everything is possible? Traditionally the design and detailing of a structure was restricted by the limitations of the fabrication process or availability of macros. With an advanced beam cutting machine, you have a 100% design freedom.

In this article you find the seven most used beam connections, prepared for welding and/or fastening. But it also provides a clear insight into unlimited possibilities for H beam coping.

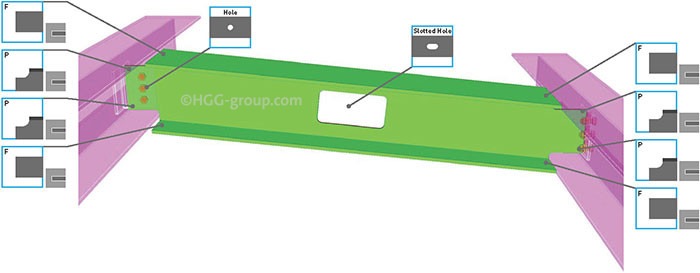

Example 1

Left: a bolted beam to beam connection, sloped shear tab connection with notches and an intermediate.

Middle: an intersection.

Right: a bolted beam to beam connection sloped with web end plate and notches

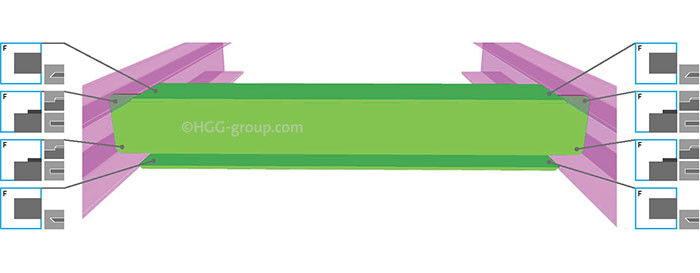

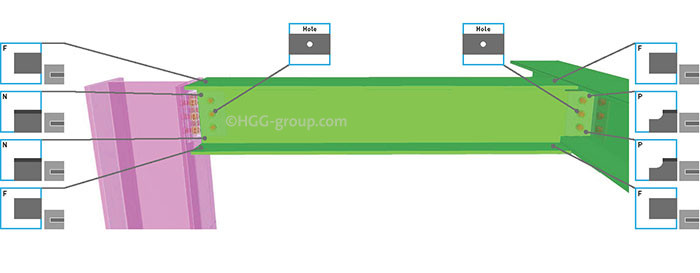

Example 2

A welded beam to beam connection, fully fixed for high performance steel structures.

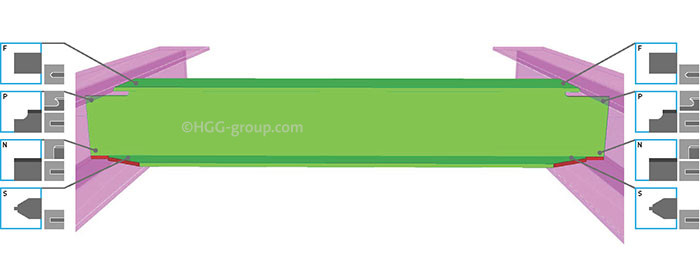

Example 3

A welded beam to beam connection, pinned with snipe for supporting members in high performance steel structures.

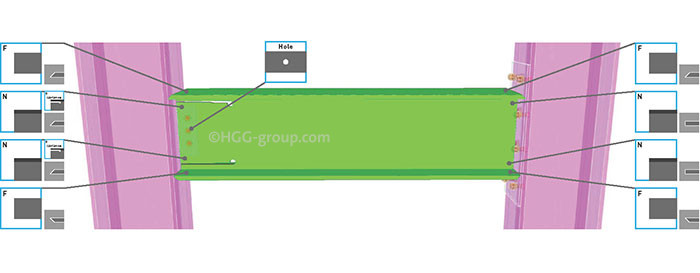

Example 4

Left: a bolted and welded column to beam connection, slotted web (SSDA) moment connection for seismic structural design.

Right: a bolted column to beam connection, extended end-plate moment connection.

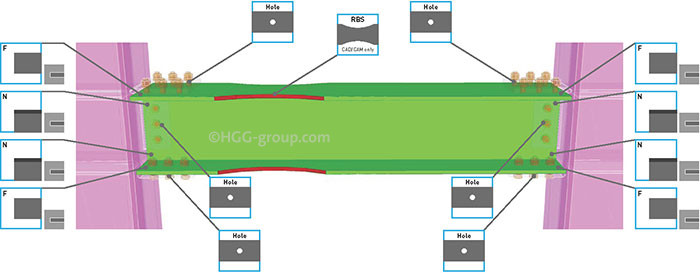

Example 5

Bolted beam to beam connection, Bolted Flange Plate (BFP) moment connection with and without Reduced Beam Section (RBS) for seismic structural design.

Example 6

Left: a bolted column to beam connection, shear tab connection without notches.

Right: a bolted beam to beam connection, shear tab connection with notches.

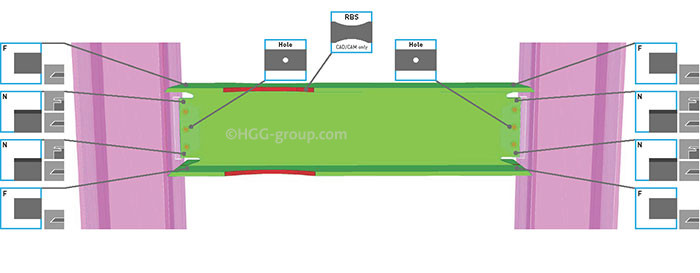

Example 7

A bolted and welded column to beam connection, Welded Un-reinforced Flange-welded Web (WUF-W) moment connection with and without Reduced Beam Section (RBS).