Did you know that you can easily save up to 30% on in-site labor costs and weld volume, using automated pipe cutting and applying smart weld preparation techniques?

In this article we explain the six most common pipe profiling shapes for ship building.

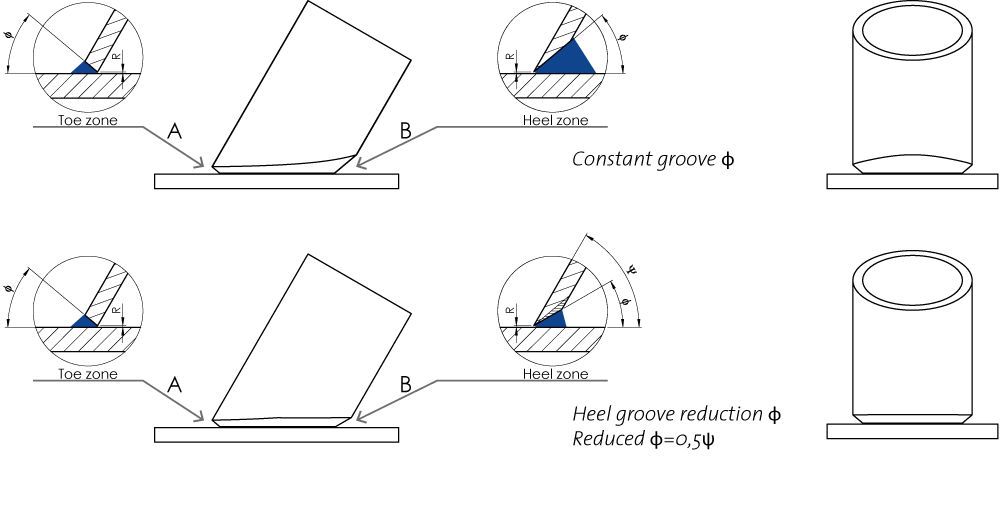

1. Chamfer

A pipe to plate connection.

Intersection geometry

• Adjustable slope.

Weld preparation

• Adjustable groove angle (φ).

• Adjustable root opening (R).

• Shrinkage compensation.

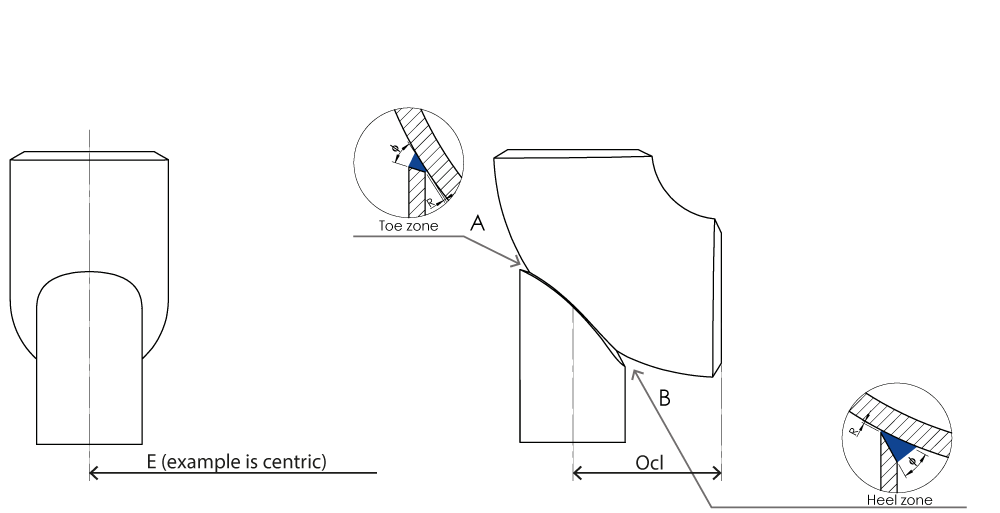

2. Elbow Saddle

Elbow support against gravity for piping industry.

Profile

• Adjustable eccentricity (E).

• Adjustable centre line offset (Ocl).

Weld preparation

• Adjustable groove angle (φ).

• Adjustable root opening (R).

• Shrinkage compensation.

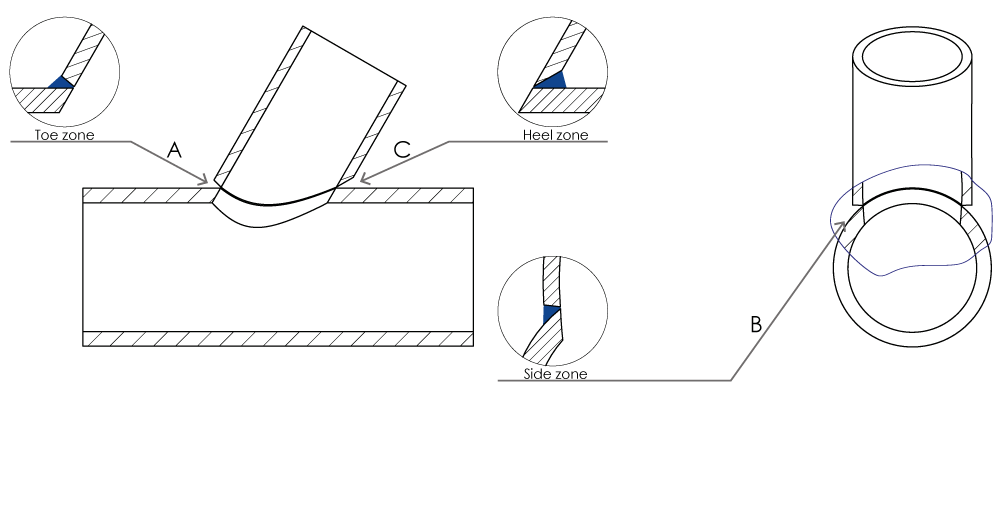

3. Hole set-on and saddle set-on

To fit a saddle on a hole for example. Saddle is shown to view an application.

Intersection geometry

• Adjustable slope.

• Adjustable eccentricity.

Weld preparation

• None for hole and groove for saddle.

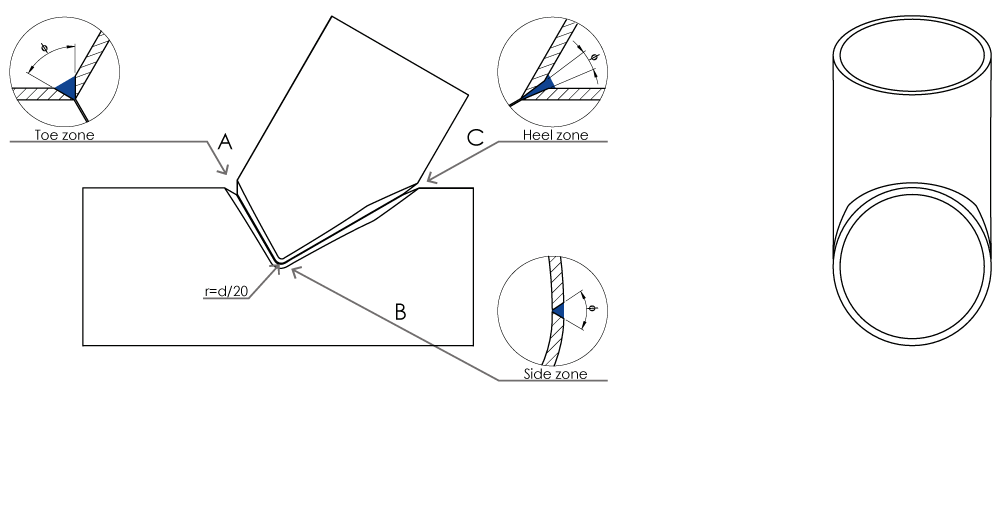

4. Mitre

To make equal diameter pipe to pipe connections for low pressure piping

Intersection geometry

• Adjustable slope.

Weld preparation

• Adjustable groove angle (φ)*.

• Adjustable root opening (R).

• Mitre Saddle: shrinkage compensation.

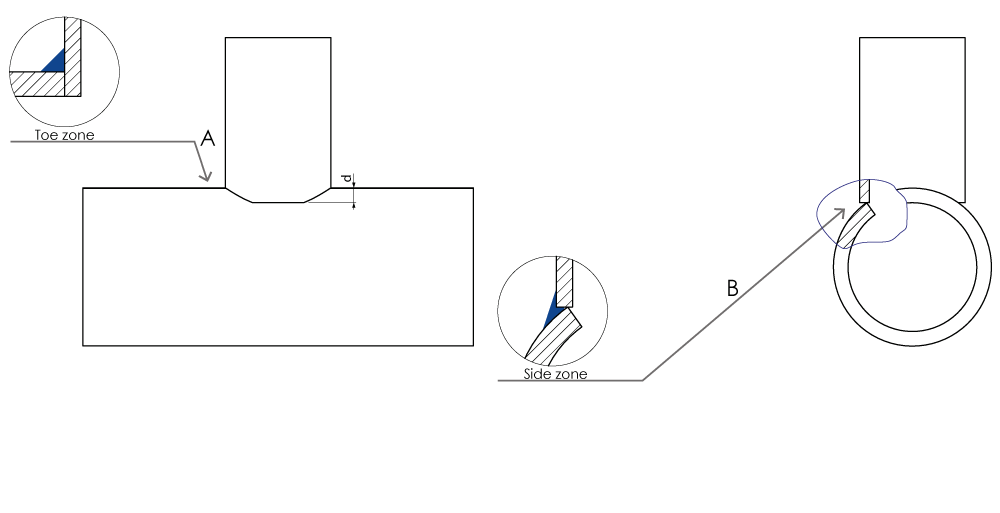

5. Nozzle set-in

A quick fit method for perpendicular piping connections.

Intersection geometry

• Perpendicular connection.

• Adjustable nozzle depth (d).

Weld preparation

• No profiled nozzle needed to weld.

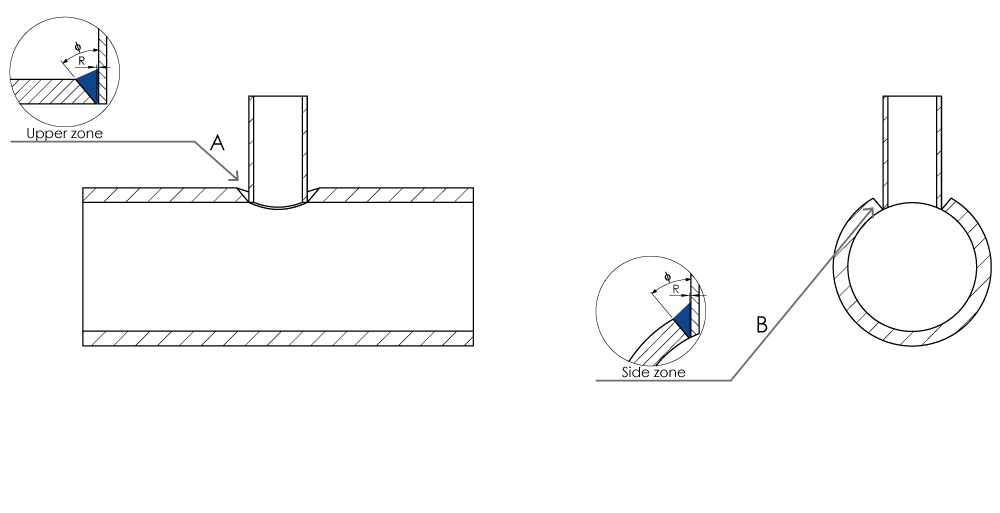

6. Saddle set-in & Hole set-in

For pressure connections with a much smaller branch pipe diameter.

Intersection geometry

• Adjustable slope.

• Adjustable eccentricity.

Weld preparation

• Adjustable groove angle (φ).

• Adjustable root opening (R).