When attempting to weld through primers at high speed, arc instability and poor wetting cause erratic weld bead contours, especially at the weld toe. Most fabrication codes demand that potential contaminants be removed from the weld zone. A fundamental necessity of welding is that the materials to be joined must be “clean”.

The same feature that prevents spatter from sticking, also causes instability of the arc and interferes with the wetting of the weld puddle in to the base metals. Increasingly, shipyards are looking to high-speed mechanized welding for improved production and reduced distortion. When attempting to weld through primers at high speeds, arc instability and poor wetting cause erratic weld bead contours, especially at the weld toe.

Furthermore, the volume of gas generated by the breakdown of the common primers may exceed the ability of a fast-freezing weld pool to out-gas, with resulting porosity, in amounts from a nuisance level to severe. There are three surfaces of each member to be joined which will require attention. Butt joints need to have the upper and lower surfaces of the plates cleaned, as well as the joint faces, which maybe square or beveled*.

*(The National Shipbuilding Research Program – December 1995 NSRP 0455 Simultaneous 3-Edge Cleaning Methods and Tooling Evaluation)

Two alternatives ways of automated edge cleaning

Two alternative techniques of edge cleaning are compared in this article; brush edge cleaning and blast edge cleaning.

Shot blast cleaning system

These machines have been specifically developed for the purpose of cleaning ship stiffeners and are not comparable to a flat plate or flat bar cleaning machine. HGG integrates the edge cleaning system with all necessary software in an automatic cycle with the profile cutting line positioned after the edge cleaning unit.

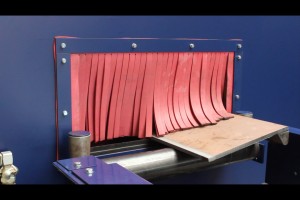

Wire brush cleaning system

With an assembly of three rotating brushes, three faces of the material can be cleaned simultaneously. The assembly adapts to the whole range of different profiles. These wire brush cleaning machines are specifically developed for the purpose of cleaning ship stiffeners. This is not comparable to a flat plate or flat bar cleaning machine. The range of movement allows the brushes to follow tilted, bent, angled and even deformed profiles.

Conclusion

The brush cleaning system is more cost effective than a shot blast unit. The initial investment is lower as are the running costs of this system. It does not need as much compressed air, it uses less energy and no abrasive grid is necessary.

However, the surface of rolled steel is often pitted with small indentations from the production process. Shot blasting removes any coating or contamination from these small craters more effectively than brushing.