HGG Case Study | Griffin Welding

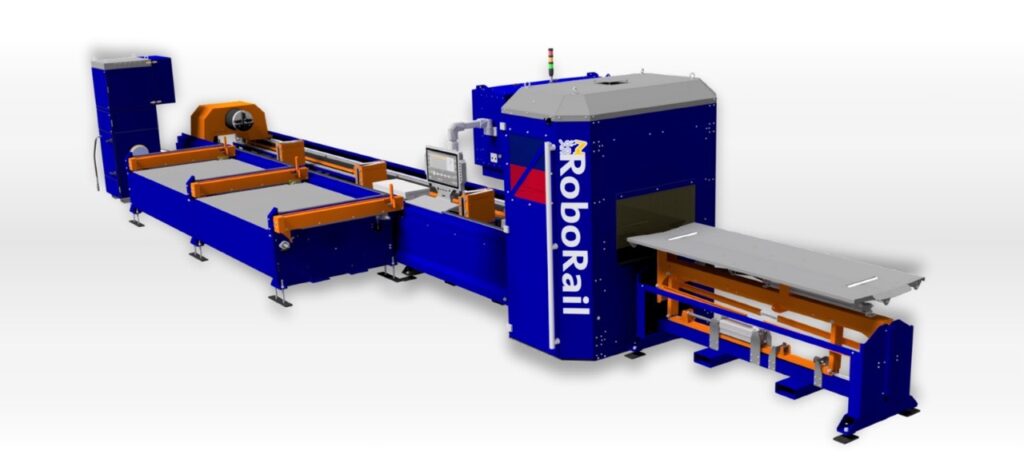

Achieving 95% Time Reduction With The RoboRail

WATCH VIDEO

About this case

Introduction

Griffin Welding, a fabrication and manufacturing company based in Waterbury, Connecticut, specializes in Department of Transportation (DOT) structures—including bridges and highway components. Owner Peter Griffin emphasizes the critical need for precise, efficient processing in their field: “In this day and age, you can do so much with the right equipment. It saves on man hours. It helps in quality.” With high production volumes involving pipe and small structural shapes, Griffin Welding needed a solution to streamline throughput and improve fabrication accuracy.

2017

Established

Griffin Welding

95%

Time Saving

Griffin Welding

2024

Installation date

RoboRail

"It Goes Together Perfectly Every Time"

“The RoboRail was definitely the best option we were looking for—a robust, industrial machine that could run every day without problems,” says Peter Griffin. Since implementation, the difference in shop flow and productivity has been transformative.

RoboRail operator Charlie Maccarella adds, “The RoboRail ensures every part is perfectly cut and marked, enabling our fabricators to assemble complex structures as if they were building with Legos. There’s no fighting anything—it goes together perfectly every time.”

This streamlined process dramatically improves output on the floor. Fitters receive precisely cut parts ahead of schedule, allowing them to focus on assembling structures without waiting on material. Charlie continues, “It’s always a good day when I’m told I’m going to be on this all day. I love finding new ways to just make everything get done faster and more efficiently.”

State inspectors have also taken notice of the manufacturing transition, recognizing Griffin Welding for delivering completed structures faster than others in the market.

From 10 Minutes to 40 Seconds: A Game-Changer for Efficiency

The numbers speak for themselves: what previously took five or six workers 10 minutes per part can now be handled by a single RoboRail operator in just 40 seconds. That kind of leap in efficiency is “a no brainer,” Peter notes. Beyond speed, the company values HGG’s ongoing support—from initial demonstration through installation and real-time service. “We’ve had not one issue,” he says. “The service from HGG has been great.”

With space-saving design, high configurability, and exceptional reliability, the RoboRail is now an integral part of Griffin Welding’s operations. “The level of production that we have now—there’s no going back at this point. So, the RoboRail stays. If we need another one, we’ll get another one and keep going.”

“From having five or six guys processing parts that take 10 minutes each, to a single operator machine that’s doing them in 40 seconds, is kind of a no brainer.”

Peter Griffin, Owner at Griffin Welding