For more than 25 years, HGG has been building robotic profiling machines that redefine what’s possible in steel cutting. Behind every one of them sits a trusted robotic foundation – but what makes HGG unique is what we build around it.

Our systems combine advanced robotics, intelligent software, and deep process knowledge to deliver accuracy, speed, and reliability that customers can count on shift after shift.

The Robot Is Just the Start

HGG has built its robotic profiling systems for over 25 years around the reliability of Stäubli robotics – a partnership that began in the late 1990s and continues today across our full range, from the PCL600 and RPC 1200 Mk3 to the RoboRail and APC.

360° Access – Total Freedom

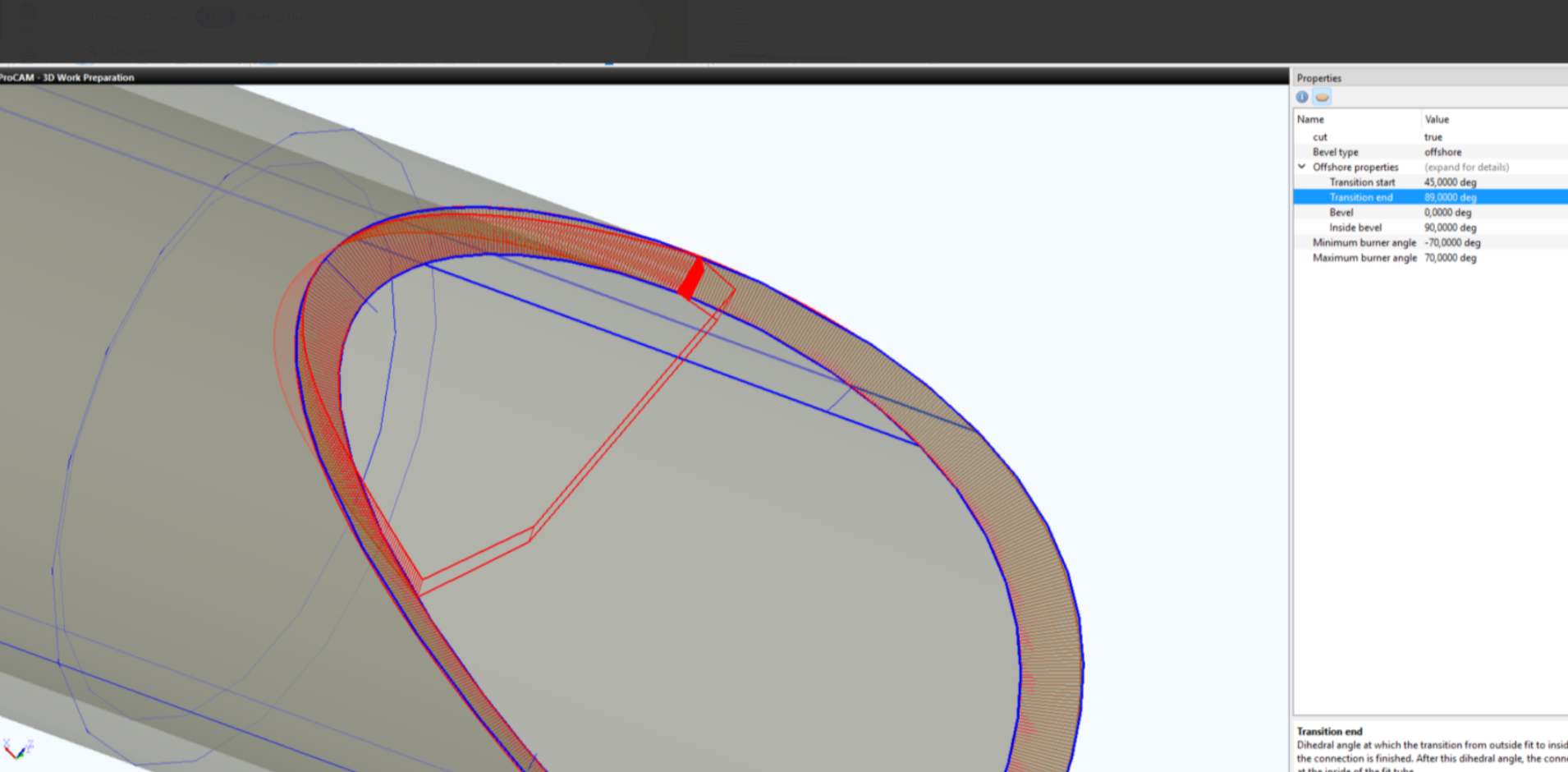

In the APC, HGG engineers pushed motion even further with Infinity Spin — full 360-degree rotation around the profile. This complete freedom of movement allows the robot to reach every surface, handle the most complex bevels and weld preps, placing exact reference and text markings and maintain precision on the fly.

The result: cleaner transitions, fewer stops, smooth over the corner cuts and a perfectly prepared edge every time. No blind spots. Just uninterrupted motion engineered for productivity.

We don't measure points, we measure shape!

Where others measure points or surfaces, HGG measures shape. Our 3D laser scanner, mounted directly on the robot arm, captures every 3D contour and radius in seconds – no contact, no delay. This means unmatched accuracy, repeatability, and speed.

Giving confidence that whatever part is cut, it will fit the first time – every time.

Software That Thinks Like You Do

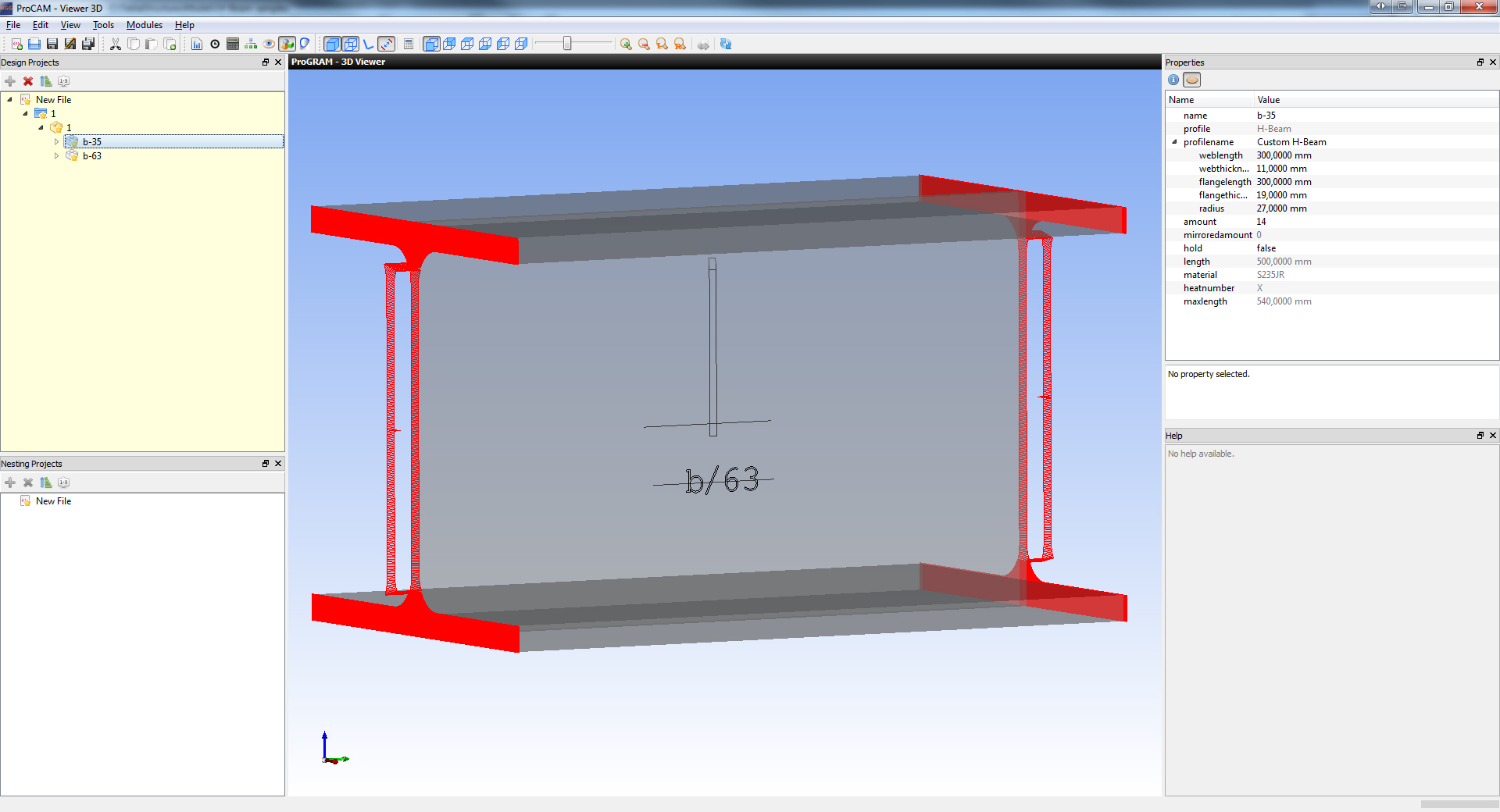

HGG’s ProCAM software connects design to production without macros or manual programming. Import any 3D model, generate cutting paths instantly, and let the machine do the rest.

This “design-to-cut” workflow eliminates programming bottlenecks and lets fabricators respond faster — especially as projects grow more complex and lead times shrink.

Open Integration – Our Philosophy

While some machine builders try to lock customers into closed ecosystems, HGG takes the opposite approach. Our philosophy is openness: we integrate with the platforms customers already use – from Tekla and Strumis to Stratus and beyond.

This freedom to connect is what makes HGG’s Coping Robots so adaptable across industries, from steel fabrication and offshore energy to shipbuilding, process, and equipment manufacturing.

The Result: Robotic Profiling That Works

When precision, uptime, and flexibility matter, HGG’s robotic profiling machines deliver. The combination of proven robotic performance, intelligent motion control, and decades of process know-how has made HGG the global benchmark for robotic steel cutting.

Because at HGG, the robot is just the beginning.