Our 3D profiling solutions

At HGG, we provide advanced 3D profiling solutions specifically tailored for the steel construction industry. Our state-of-the-art machinery ensure precision, efficiency, and versatility in cutting steel beams, pipes, and other structural components, making your fabrication processes faster and more cost-effective.

Featured

New

Featured

Machine comparison

We help you find the right machine for your needs. To assist you in selecting the best machine for your fabrication, here’s a comparative overview of our key models:

| Features | RoboRail | APC | RPC 1200 MK3 | Cutting features | PLASMA | HIGH DEFINITION PLASMA | HIGH DEFINITION PLASMA |

|---|---|---|---|

| Power Sources | Hypertherm | Hypertherm | Kjellberg |

| Profile Types |

|

|

|

| Max. Dimensions | 250 mm / 10" | 800 mm / 32" | 1220 mm / 48" |

| Max. Material thickness | 25 mm / 1" | 50 mm / 2" | 75 mm / 3" |

| Max. Weight | 550 kg. / 1.200lbs | 5.500 kg. / 12.000lbs | 12.000 kg / 26.455lbs |

| CAD / CAM | DSTV, STEP | DSTV, STEP | DSTV, STEP |

| Software Integrations |

Tekla,

SDS2,

Pypeserver

|

Tekla,

Strumis,

Powerfab,

SDS2,

Pypeserver

|

Tekla,

Strumis,

Powerfab,

SDS2,

Pypeserver

|

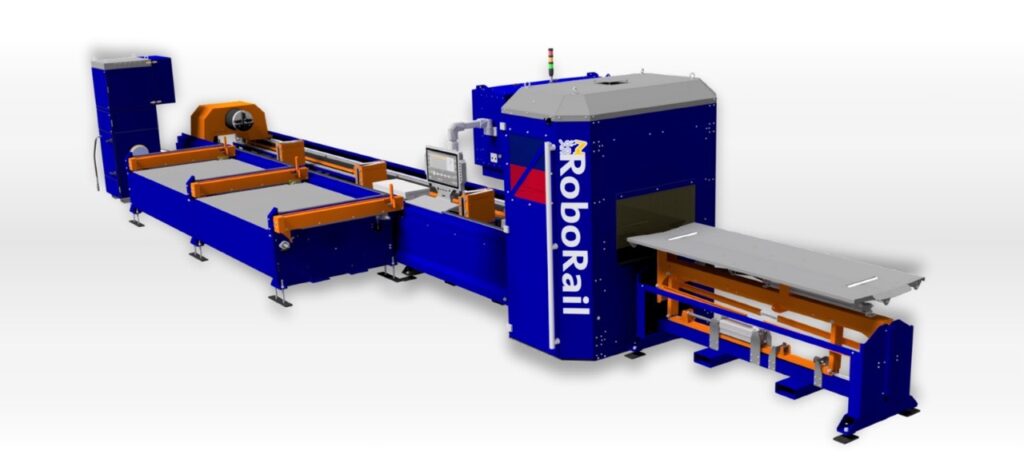

| Features | Roborail |

|---|---|

| Cutting features | PLASMA |

| Power Sources | Hypertherm |

| Profile Types |

|

| Max. Dimensions | 250 mm / 10" |

| Max. Material thickness | 25 mm / 1" |

| Max. Weight | 550 kg. / 1.200lbs |

| CAD / CAM | DSTV, STEP |

| Software Integrations |

Tekla,

SDS2,

Pypeserver

|

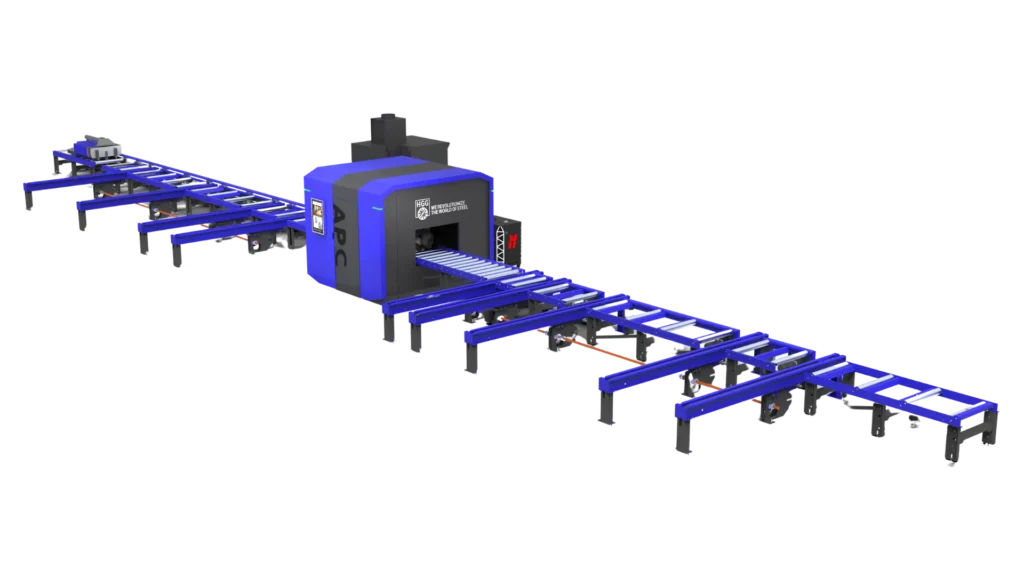

| Features | APC |

|---|---|

| Cutting features | HIGH DEFINITION PLASMA |

| Power Sources | Hypertherm |

| Profile Types |

|

| Max. Dimensions | 800 mm / 32" |

| Max. Material thickness | 50 mm / 2" |

| Max. Weight | 5.500 kg. / 12.000lbs |

| CAD / CAM | DSTV, STEP |

| Software Integrations |

Tekla,

Strumis,

Powerfab,

SDS2,

Pypeserver

|

| Features | RPC 1200 MK3 |

|---|---|

| Cutting features | HIGH DEFINITION PLASMA |

| Power Sources | Kjellberg |

| Profile Types |

|

| Max. Dimensions | 1220 mm / 48" |

| Max. Material thickness | 75 mm / 3" |

| Max. Weight | 12.000 kg / 26.455lbs |

| CAD / CAM | DSTV, STEP |

| Software Integrations |

Tekla,

Strumis,

Powerfab.

SDS2,

Pypeserver

|

Get the full overview:

Want to explore your options? Download our comprehensive Steel Construction Brochure featuring our key steel construction solutions. Discover the key features of the machines, performance details and the inner workings of the machines.

Success stories in the steel construction industry

Discover how our solutions have transformed fabrication processes for various steel construction companies worldwide:

Expertise beyond Steel construction: Precision pipe cutting and more

While HGG is renowned for its advanced solutions in steel construction, our expertise extends across a range of industries where precision and reliability are paramount such as shipbuilding, process and offshore. Our pipe profiling machines have an established track record and have been market leaders for multiple years. They provide optimal torch positioning with multiple CNC axes and

Unmatched 3D Pipe cutting capabilities.

Up to 12 times faster than manual cutting including weld preparation.

Engineered for heavy duty work.

Software developed for profilers by profilers

At HGG, we don’t just provide advanced cutting machines, we have also developed ProCAM software that allows you to easily turn your CAD-designs into cutting files. From single parts to complete assemblies. Check the parts in the 3D viewer, nest the parts with HGG’s powerful nesting module, and adjust them before generating the cutting files.

About us

We are committed to giving you the competitive advantage in your market. Helping you turn your fabrication process in a streamlined and automated manufacturing environment. Trusted by the world’s leading companies in construction, shipbuilding, offshore and pipe processing industries.

We automate craftsmanship to give the world of steel the freedom to create.

3

International locations

170+

Employees worldwide

1100+

Machines installed

60+

Installation countries

Quickly find the machine that best supports your bottom line!

Our selection aid helps you identify the ideal solution for your specific needs, based on your cutting requirements. After answering the questions below, you’ll be automatically guided to the most suitable machine. There, you’ll find detailed product information, videos, technical specifications, and the option to request a quote directly.

Looking for sales support?

Reach out directly to our sales manager for expert advice on solutions. Call or email me directly – I am here to help!

Stay up to date

Subscribe to our newsletter to get the latest on our solutions and developments.