HGG’s ProCAM software includes a wide range of tools designed to simplify and automate profile cutting workflows. One unique feature that deserves special attention is its STEP import functionality, where users can add weld bevel preparations directly to imported models, improving both efficiency and accuracy in production.

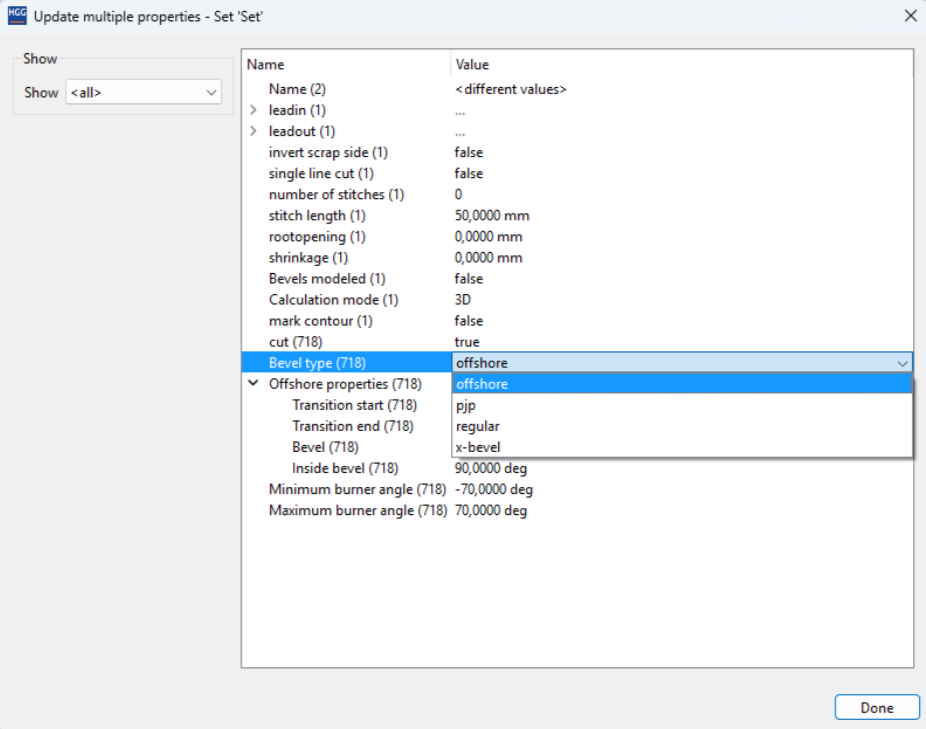

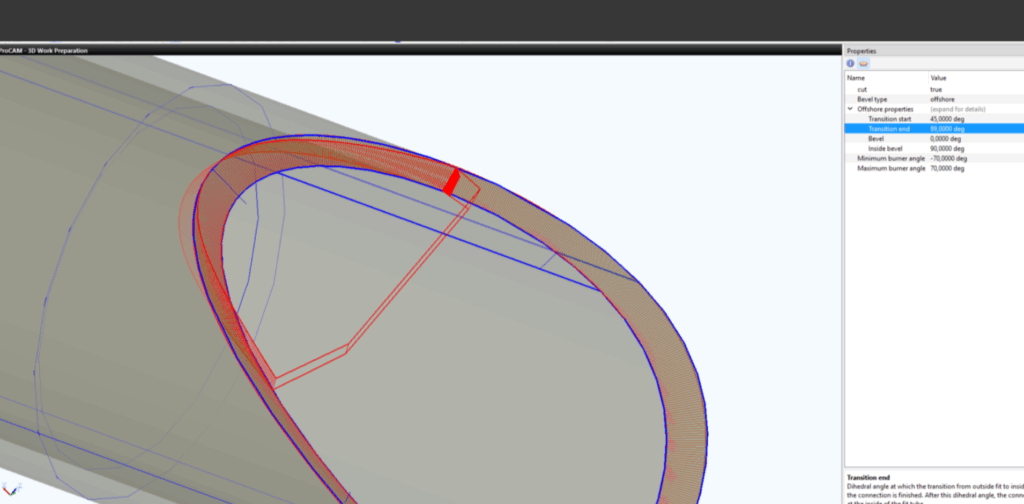

Within the STEP import functionality, users can simply select a reference surface – even an irregular surface obtained from a 3D scan of a pipe surface – and add a weld bevel to it. Multiple bevel types are available, including Offshore, PJP, Regular, and X-bevel. This is particularly beneficial for offshore fabrications, where double-sided and complex bevels are frequently required to meet demanding welding standards.

Eliminating separate macro programming

ProCAM’s STEP import supports not only simple bevels, but also complex double bevel preparations generated directly from 3D geometry. This eliminates the need for separate macro programming or manual parameter setup, enabling a smoother transition from design to cutting.

By making these advanced bevel options accessible through STEP import, ProCAM empowers users, especially in the offshore sector, to produce accurate, weld-ready components faster and with greater consistency. Helping you across every stage of your production.